Cómo realizar configuraciones precisas más rápido

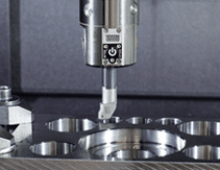

1) El sistema modular CKB permite combinaciones ilimitadas aparte del número de componentes que los usuarios pueden apilar para un ensamblaje.

En cualquier ensamblaje, el número de componentes debería limitarse a cuatro o cinco, sin incluir los portainsertos del cabezal de mandrinado. Dado que normalmente existen dos o tres opciones de longitud para una combinación determinada de cono y conexión, la mayoría de las aplicaciones solo requieren dos o tres componentes diferentes (vástago, extensión/reducción, cabezal de mandrinado). Cuando los usuarios necesitan más longitud de calibración, independientemente de la profundidad del mandrinado, la mejor opción es usar la conexión CKB más grande en el extremo del vástago y adaptadores de reducción para minimizar la relación longitud-diámetro (L:D) del ensamblaje. Cuando los requerimientos de profundidad exceden lo que permiten los adaptadores de cono estándar, se pueden usar extensiones, pero se recomienda un máximo de dos.

Para diámetros de mandrinado de 0.787" a 1.614" (20 mm a 41 mm), las barras de carburo de vástago cilíndrico CKB1 a CKB3 pueden ser una alternativa. La mayor rigidez de estas barras permite relaciones L:D de mandrinado de hasta 10:1 y, combinadas con un portaherramientas hidráulico, proporcionan amortiguación de vibraciones. Superponiendo ligeramente este rango (1.260" a 8.000") se encuentran los cabezales de mandrinado Smart Damper, que incluyen un ensamblaje interno para absorber vibraciones. La opción final es el ensamblaje modular CKN, una versión especial del CKB que es compatible cruzadamente pero utiliza tres tornillos de conexión en lugar de uno y presenta una extensión de aluminio para reducir el peso de la herramienta.

2) ¿Cómo han cambiado los cabezales de mandrinado digitales la fiabilidad del proceso y/o la capacidad en la industria aeroespacial?

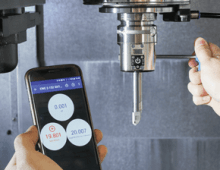

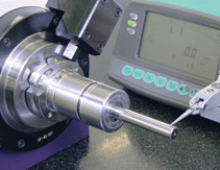

Eliminan las conjeturas en el ajuste de tamaño. En lugar de medir la rotación de entrada del dial de ajuste, estos cabezales colocan escalas de desplazamiento a lo largo del portaherramientas para medir el recorrido lineal y pueden mostrar correcciones de diámetro de 1 µm. Además, el desplazamiento de sujeción se puede ver con estos cabezales.

Almacenar valores de ajuste incremental de diámetro en el cabezal permite a las empresas realizar un seguimiento de la vida útil de los insertos y avisar a los operadores cuándo cambiar las esquinas de los insertos cuando los valores de ajuste alcanzan un valor predeterminado. De lo contrario, el operador puede volver a poner a cero la pantalla para que el valor de compensación en el cabezal sea igual al siguiente ajuste.

Conectado a la aplicación BIG KAISER vía Bluetooth, el valor incremental del cabezal de mandrinado fino EWE puede ingresarse en los parámetros predefinidos para indicar el diámetro de salida real de la herramienta. Con la información de tolerancia añadida para el mandrinado, el dispositivo conectado indica dónde se encuentra el ajuste real dentro del rango objetivo. El cabezal almacena hasta 200 ciclos de esta información (diámetro objetivo, tolerancia, ajuste incremental) para cada ajuste junto con la fecha y hora, proporcionando trazabilidad del proceso para certificaciones ISO y otras.

3) ¿Qué tipos de opciones de acabado de agujeros de precisión aeroespaciales permiten los cabezales de mandrinado fino?

Muchos componentes aeroespaciales están fabricados en aluminio o magnesio de alta resistencia, lo que facilita manejar agujeros de tolerancia ajustada, incluso con herramientas desarrolladas hace décadas. Sin embargo, en muchas aplicaciones, los agujeros usan un buje de acero endurecido insertado a presión, lo que requiere que el tamaño final se realice con rectificado de plantilla. El proceso es lento y requiere un operador altamente calificado. Las máquinas CNC equipadas con nuestras herramientas de mandrinado fino CK usando nuevos grados de nitruro de boro cúbico (CBN) han reemplazado con éxito el rectificado de plantilla. Incluso los agujeros de plantilla menores de 0.25" han sido reemplazados con cabezales de mandrinado fino estándar.

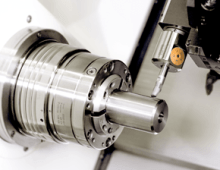

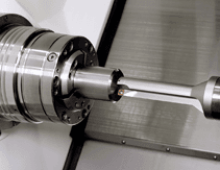

4) ¿Cómo han usado los fabricantes aeroespaciales BD en centros de torneado para mandrinar agujeros transversales con herramientas motorizadas?

Los componentes del tren de aterrizaje tienen muchas aplicaciones que normalmente se realizan en torno. Sin embargo, los enlaces con agujeros transversales de precisión requieren mandrinado fino para completar el trabajo. Cuando los tornos con cuarto eje y herramientas motorizadas se popularizaron, Kaiser tuvo que adaptar nuestros cabezales de mandrinado fino para procesar las piezas completamente. Una limitación era mantener la proyección de la herramienta lo más corta posible debido al corto recorrido del eje Y. Con la mayoría de las herramientas motorizadas usando pinzas ER, desarrollamos una serie de cabezales de mandrinado fino que reemplazan la tuerca de sujeción ER estándar, haciendo la herramienta ultra corta y muy rígida. Mandrinar agujeros transversales en un torno se volvió muy fácil con herramientas disponibles.

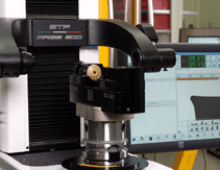

5) ¿Qué recomienda BIG DAISHOWA para mandrinar agujeros de precisión en piezas aeroespaciales usando cabezales angulares?

Un gran contratista necesitaba reemplazar un proceso manual para mandrinar los agujeros de pasador que sujetan los conjuntos de alas en componentes de fuselaje comercial. La única solución práctica era el mandrinado con cabezales angulares.

Aunque el proceso parece simple, había un problema básico: si el cabezal angular no es verdaderamente de 90°, la herramienta de mandrinado no producirá un agujero perfectamente redondo. Piense en una columna de máquina que no está perpendicular a la mesa. Al rotar el husillo y recorrer la mesa, generará una forma elíptica. El mismo resultado ocurrirá si el cabezal angular es, por ejemplo, 89°; nunca seguirá un agujero perfectamente redondo. La precisión del agujero terminado solo es posible si la tolerancia del cabezal angular se controla cuidadosamente.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.

Añadir nuevo comentario