Five-Axis Machining: Benefit of Underside Clamping

When clamping for five-axis machining, access to the part is an issue many metalworking shops face. In a recently published article in Modern Machine Shop, our workholding product manager, John Zaya, shares information on a solution to this problem.

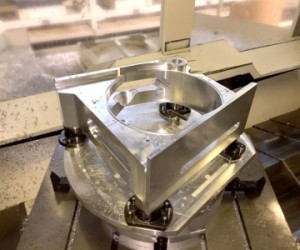

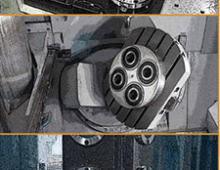

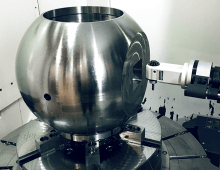

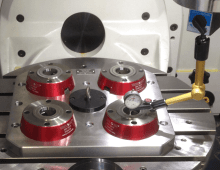

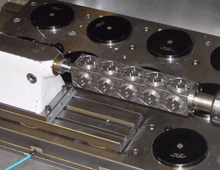

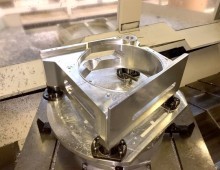

The article goes on to discuss BIG KAISER’s Unilock system, which provides for repeatable, quick-change workholding using a

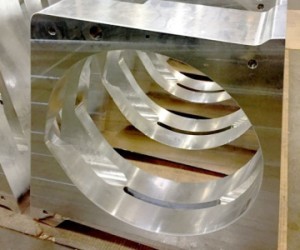

receiver that clamps on a precision knob. Developed and long used for setup-time reduction, the system is now finding applications in five-axis machining not primarily because of the quick-change clamping, but instead because it offers a secure way to clamp the part entirely from underneath.

In the article, John states, “The option to clamp exclusively on the underside of the part leaves the workholding essentially hidden—concealed from all these interferences by the workpiece itself. The system simply requires either preexisting holes in the part or the addition of holes for affixing the knobs used for this clamping.”

Five-axis machining has become one of the most important technologies in metalworking today. The increased use of five-axis machining in general production means shops must evaluate other components of their processes, such as workholding,

To read more about BIG KAISER’s Unilock system and the solution it offers, read the full article titled “Workholding System Suits Five-Axis Machining by Clamping Underneath” here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.