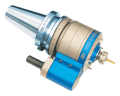

HIGH SPINDLE

HIGH SPINDLE is an innovative gear-driven system that enhances the performance of existing machining centers by multiplying spindle speed 4, 5, or 6 times, improving both drilling and end milling operations.

Reinforced Gear Driving System for Smooth Operation

HIGH SPINDLE has been evolving since 1970, featuring planetary gears ensuring smooth operation with minimal heat generation and high torque transmission.

Reduction of Load on Machine Spindle

Prolong the life of your machine spindle—HIGH SPINDLE diminishes excessive motor and bearing loads, crucial for continuous high-speed operation.

1.7 Times Increased Rigidity

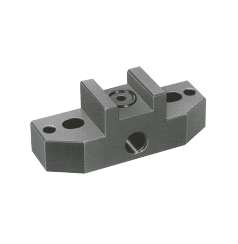

Experience enhanced rigidity with a larger diameter body, spindle equipped with double angular contact bearings, and a reinforced locating pin assembly.

Multi-Directional Coolant Supply

Experience adaptable universal coolant nozzles capable of adjusting to the cutting tool length, ensuring optimal coolant delivery to the cutting edge for enhanced performance.

Pinpoint Coolant Jet for Shorter Cutting Tools

With a 1/8 pipe tap thread, our HIGH SPINDLE accommodates various coolant-jet nozzles, providing precise coolant delivery to the cutting edge of shorter tools (BCV/BBT taper models only).

- Spindle Speed Multiplication: Multiply spindle speed by 4, 5, or 6 times, enhancing performance in drilling and end milling operations.

- Reduced Spindle Load: Diminish excessive motor and bearing loads, extending the lifespan of the machine spindle.

- Enhanced Coolant Delivery: Adaptable coolant nozzles ensure optimal coolant delivery to the cutting edge, improving tool performance and efficiency.