How to Choose a Tool Assembly Device

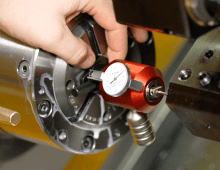

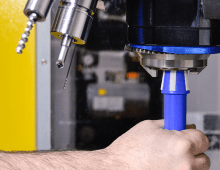

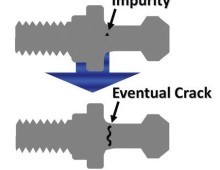

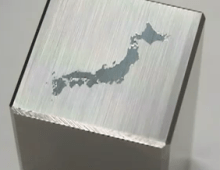

BIG DAISHOWA’s tool assembly products are crucial to efficiency and getting the most out of your expensive equipment. These products allow operators to quickly and safely setup tooling in a way that won’t damage costly tool holders, shanks and machine spindles – and, in turn, ensure your expensive tooling performs at the highest level for as long as possible.

While we provide an array of unique tool assembly devices, it is often challenging to ensure you’re choosing ones that best fit your team’s current and future needs.

Tool Pro – This is a unique tool holding device for the assembly and disassembly of tapered V-flange tooling and modular tooling systems.

Tool Pro Vario – This quick-change system uses one permanently mounted base unit and multiple adapters for different types and sizes of tool shanks.

Tool Pro Spin – Full 360-degree radial tool rotation, while clamped, permits easy access to large diameter tools and makes it ideal for changing inserts on large face mills without removing the tool from the drive keys.

Tooling Mate – When securely fixed to a bench with four mounting bolts, this tool assembly fixture with modular adapters accommodates different shank sizes and allows for removal of pullstud bolts and tools.

Kombi Grip – The Kombi Grip's innovative two-way clutch needle roller clamping system assures secure clamping at the tool flange periphery.

In order to easily compare our line-up of products, we’ve pulled together a helpful graphic that displays the features and functions of each product. If you still have questions on which tool assembly device will work best for your equipment, our team of engineers will be happy to assist you.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment