The Meaning of the Word “Precision?”

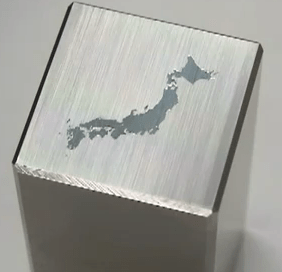

Watch this video of a map of Japan being embossed to .0002" in height.

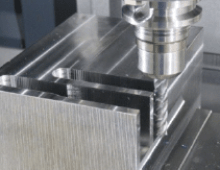

Take a look at this map of Japan being milled.

While the very largest manufacturers are able dedicate niche or single-purpose machines to new alloys, composites, plastics and the like, what’s a small to medium-sized manufacturer to do during this advent of non-traditional materials? Smaller manufacturers’ greatest strength has always been agility and flexibility, and leveraging these qualities can open the door to new materials requiring higher than usual RPM’s. And these speeds mean precision, as this milled map of Japan proves.

Today’s CNC machines can be retrofitted with the necessary environmental controls to allow manufacturers to run a mix of materials.

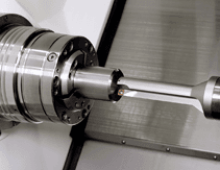

Consider, for instance, the Air Power Spindle; this tool is able to reach incredibly high speeds on any existing machine completely independent of the machine spindle – the RBX5 unit goes 40-50,000 RPM, and the RBX-7 goes 60-80,000 RPM. And, perhaps most importantly, with an air-driven spindle, speeds are variable based on air pressure. This allows smaller to medium-sized machine shops to flex their muscles and address new composites with traditional machines.

And air-powered functionality isn’t limited to smaller shops. Even medium-sized to larger companies, including Royal Engineered Composites, a plastics thermoformer recently featured in Modern Machine Shop, turned to an air-powered spindle to complete a job requiring a total of 7,000 holes measuring just 0.051” in diameter. For such small-scale drilling operations in an extremely abrasive material, the company uses BIG Kaiser’s RBX-7 at 70,000 RPM. Read about how they tackled their problem here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.