Our Most Overlooked Products

We recently released our nearly 600-page catalog, High Performance Tooling Solutions Vol. 4. With thousands of part numbers listed, product selection can be a bit overwhelming. We’ve selected a few overlooked products and services that can help guarantee higher performance for your shop.

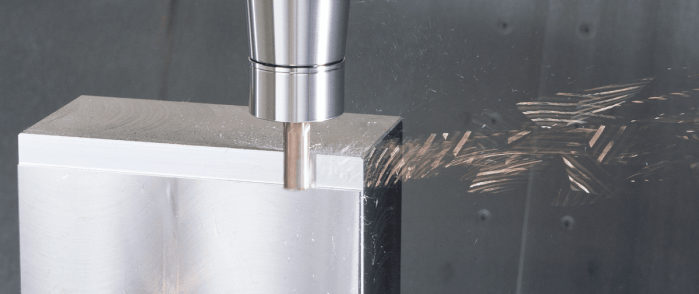

MEGA E Holders

The idea of a be-all-end-all tool holder is a myth. Every situation is different, and every tool holder offers its own unique advantages and disadvantages. Over Ø1” and you’ll probably want to use a milling chuck, while micro tools under Ø3mm will usually call for a micro collet chuck.

That being said, there are often times when more than one tool holder will work because of the overlap of product ranges. Ø1/2” tooling, for example, lies in a gray area because nearly all of our tool holders are an option. So, it’s very easy to be inundated with options and for a holder like MEGA E to get lost in the crowd.

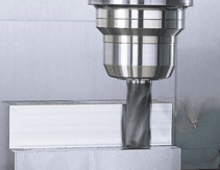

MEGA E chucks were created specifically for intermediate-sized tooling (Ø1/8-1/2”), which means that, by design, they are somewhat of a niche product. They are excellent for high-speed finish end milling. Can other tool holders perform high-speed finish-end milling in this range? Certainly. But with a beefy, tapered body and long, high grip-strength collets, MEGA E combines the advantages of a collet chuck with the rigidity of a milling chuck. Or, if you’re more of a pessimist: it’s too bulky for most small applications and yet not quite the gripping strength of a milling chuck.

It depends on your point of view, which may explain why this holder hasn’t soared to the same height of popularity as some of our others.

A lot of people don’t realize this, but for BT30 applications in the Ø1/8-1/2” range, MEGA E has the shortest gage length available compared to our other holders. It also has the largest body diameter of all comparable holders for that range. This means that for finish end milling in a Fanuc Robodrill, Brother Speedio, Kitamura Mycenter, etc., MEGA E is arguably the ideal holder, yet you rarely see it used.

| Ø1/2" Tool holder Options | Shortest Length Available (mm) | Body Diameter at nose (mm) | Catalog Number |

|---|---|---|---|

| MEGA New Baby | 60 | 35 | BBT30-MEGA13N-60 |

| MEGA ER | 60 | 35 | BBT30-MEGAER20-60 |

| MEGA E | 50 | 42 | BBT30-MEGA13E-50 |

| Hi-Power Milling/MEGA DS* | 63.5 | 35 | BBT30-HMC.500J-2.5 |

| Hydraulic** | 63.5 | 33 | BBT30-HDC.500-2.5 |

| Side Lock | 63.5 | 35 | BBT30-EM.500-2.5 |

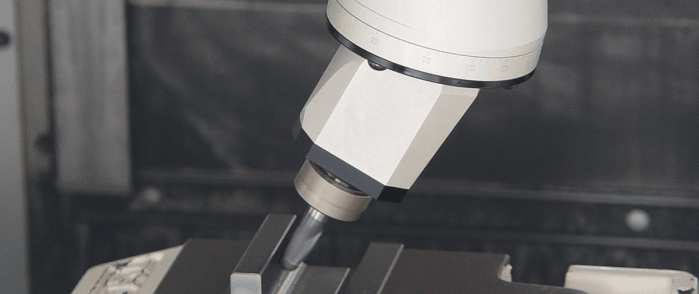

AGU30 Angle Heads

“Why would I use an angle head that can only rotate 30° from centerline when there’s one that can go from 0 to 90°?”

More often than not, that’s a question we receive whenever someone is looking for a universal angle head. We offer two versions: AGU, which has full 0-90° adjustability, and the lesser known AGU30, which has limited 0-30° adjustability. The problem with the above question is that it assumes that our AGU and AGU30 have the same internal design and are equally rigid, which can’t be further from the truth.

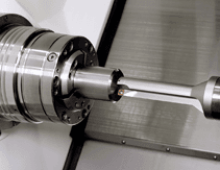

Angle heads in general are fragile, or at least more fragile than most people initially believe, and universal angle heads are no exception. In most cases, people misunderstand or overestimate their abilities. They are spindle attachments, not spindles themselves. While the AGU heads use a complex gear-driven system that you would expect from a universal angle head, our AGU30 heads use a constant-velocity (CV) joint like what you would see in an automobile axle. This results in a much more robust angle head, but at the same time limits their angle to 30° or less. However, if your application requires work in this range, the AGU30 is by far the superior option.

Ask yourself how many shops truly need the full versatility of 0-90° adjustment that don’t already have a 5-axis universal spindle on the machine? People largely look at these heads with one, maybe two, oddball angles in mind, so they don’t use the vast majority of the range. They’re essentially trying to retrofit a 3-axis machine to be able to do a very specific high-production job that is otherwise confined to the realm of 5-axis.

So, if your angle is within the 0-30° AGU30 range, it is almost always the better option because chances are you’re not going to be doing much else with it. They’re less flashy than the fully universal AGU, but these units can take much more of a beating and they cost less.

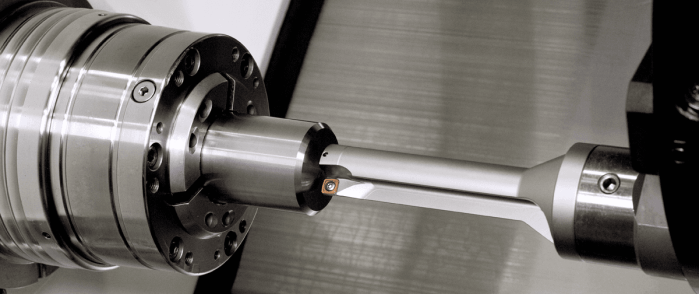

Insert Drills

Did you know we offer an expansive line of insert drills? With the U.S. market being saturated as it is with cutting tools, we have found a place at the extreme ends of the spectrum that established companies often neglect: micro tools (<Ø3mm) from Sphinx at one end, and massive insert drills for large diameters at the other.

These insert drills have a steel body, with indexable carbide inserts acting as the “tip,” perfect for those who don’t want to spend a small fortune on large solid carbide tools. They conveniently come with our modular connection on the back, so the same shanks you use for your boring tools can be used for the drills; assuming, of course, you have enough horsepower in your machine.

What this means is that we offer complete holemaking solutions for Ø.630-2.875” – drilling, chamfering, rough boring and finish boring. All of this over that entire range, for at least 2xD depth but typically even longer than that, depending on specific diameter.

How do we manage to cover such a large range if the drills come in 1/16” or 1mm increments? It’s because we also offer an adjustable drill holder, with which you can offset the drill centerline and rotate it eccentrically to cut any conceivable diameter in between.

Next time you or your customer have a bore you need to make from scratch, give us a call first. It might be the only call you need to make.

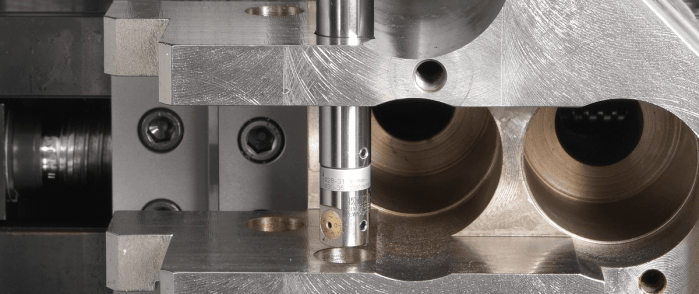

EWB Boring Heads

Between our tried-and-true EWN 112 lines and our state-of-the-art digital Bluetooth EWE fine boring heads, there is the EWB standing in the shadow. The B stands for balance, auto-balance to be more precise. That’s not to imply that our other heads aren’t very well-balanced; they are. But as you adjust out the diameter on EWB, there is a built-in counterweight that, in unison, adjusts in the opposite direction.

A standard boring head is precisely balanced to some diameter in the middle of its range, but with EWB you can rest assured it’s almost perfectly balanced no matter the diameter setting. This head is a great option in applications that call for a tight geometric roundness tolerance in a bore or for higher speed applications, where unbalance tends to be less forgiving.

If you, for example, have 10,000 aluminum holes to bore, you’ll most likely want to use a PCD (diamond) insert, which will effectively double your cutting speed and cut cycle time in half. EWB is especially complementary in this scenario, as it will maintain balance even at these incredibly high speeds.

EWB costs more than a standard EWN or 112 head, so people don’t tend to use it if they don’t have to. But what most people don’t know is that for some models, like smaller EW sizes and our 112 head, the EWB version only costs 15-25% more. For the example above, you would see a return on investment almost right away.

Is it true to say you “might as well” choose EWB in most cases? That depends, but it’s certainly not a huge jump from EWN. The extra balance is good insurance and who knows what you might need it for in the future.

In-house Services

While many are familiar with our repair department at our suburban Chicago facility, fewer are familiar with some other services that we provide.

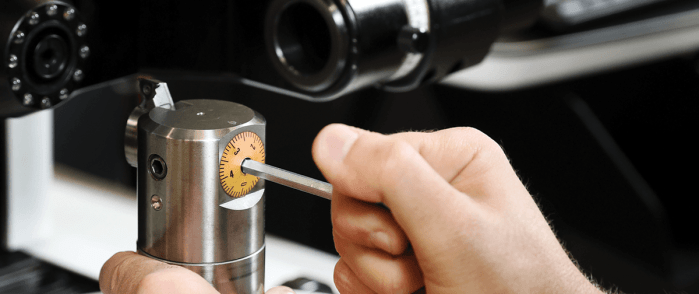

As the makers of some of the finest quality boring heads in the world, naturally we also provide some of the finest quality presetters in the world. However, a high-quality presetter is a much larger investment than a boring head, so not everyone has one. Or maybe you just aren’t confident assembling or presetting a modular boring assembly. Whatever the reason, we are happy to offer complimentary presetting on any of our boring heads, if it is requested.

We also offer other convenient services for a reasonable charge. Do you need boring heads or tool holders balanced? We can help with that! In fact, special tools, high-speed shell mill holders, etc. require balancing before they can be used. We can balance any holder on request, to the widespread ISO 1940-1 standard or the new ISO 16084, which is specific to rotating tools and tool systems.

Do you have an aging Mori that uses DIN B flange coolant or use Balluff chips for tool management? We can modify almost any of our standard tool holders and boring tools to be compatible with these systems, with little to no increased lead time.

We also are capable of cutting notches, coolant holes, and marking tools, or shortening shanks, among other things. We accept most modification requests, just let us know what you need and we will be happy to help you.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment