Practical work on laand d ratio

The One Tenth = 10% Rule and the Effects of Runout

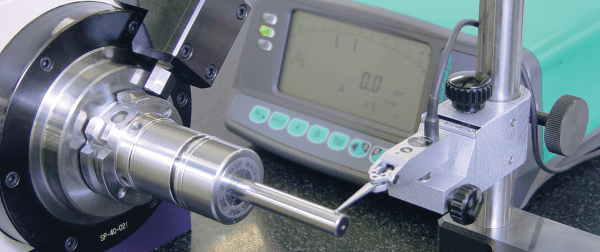

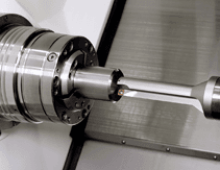

Runout is one of the sneakier issues machinists and tool managers must deal with. Put simply, runout is variation in the diameter of a cutting tool at certain points as it rotates. It’s almost impossible to recognize in-process and difficult to diagnose after the fact. The potential sources are numerous and different.

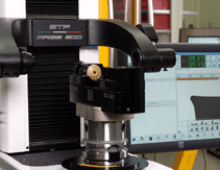

When it comes to the holder, the lower the ratio of taper-to-taper contact, the more runout. (We machine holders to sub-micron tolerances, achieving at least 96% contact.) The same goes for the point of contact between the cutter and the holder.

The standard collet angle, for example, is 16 degrees, which provides an appealing clamping range. However, a chuck at 12 degrees will make more contact and offer more control of the tool. Solid nuts also introduce more risk of runout in collet assemblies. The last few degrees of wrench pull twists the collet, while a bearing nut maintains low torsion for smooth, concentric clamping.

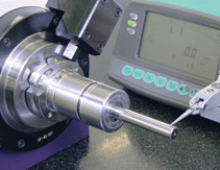

The size of the tool assembly plays a role; the length-to-diameter ratio and mass are going to affect force as it spins. The larger the tool, the more resistant it is to runout. With tools 3/4"-diameter tools or larger, runout of 0.0005" may not impair tool life. However, with smaller tools runout may need to be much better.

We’ve also found, in our own research, that the cutter material reacts to runout differently. We tested nearly identical carbide and HSS drills with the same runout and found carbide to be more sensitive to runout.

Another variable that’s even more difficult to control or diagnose is that cheaper, mass-produced holders and cutters can have extra runout essentially built in. It’s just not easy to make high-performance holders and cutting tools. Holders, specifically, need to deliver clamping force, concentricity, rigidity and balance for high speeds. A cheap OEM pullstud made of weaker metal is susceptible to deformation that can affect centerline alignment too.

That said, even the best holder cannot deliver superior performance in a worn or imprecisely ground spindle. Keep those gage bars handy, especially if you’re doing high-speed work when centrifugal forces increase exponentially.

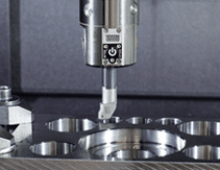

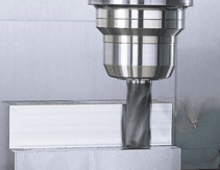

So, if runout is tricky to identify, what’s the bottom line? If a drill or mill doesn’t run concentric to its centerline, more forces are generated in the direction of the biggest margin. This causes just one side of a tool to work. Even if this results in on-spec parts, and it can, the cutting tool is essentially being wasted.

Each tooth should hit at the exact same spot along the workpiece. If one tooth is hitting the workpiece more frequently, it’s doing the bulk of the work. In other words, if you have six teeth on a cutter but the tool is runout out by more than a thousandth of an inch, you’re likely only using three of the teeth.

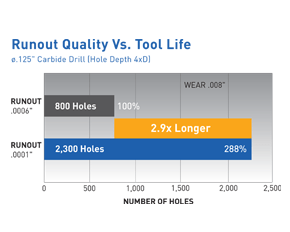

To calculate the impact of this on tool, we use the One Tenth = 10% Rule. That is, one tenth (.0001”) of runout will increase or decrease tool life by 10%. In other words, if five tenths of runout is your baseline and you swap in a holder that that reduces runout to one tenth, tool life should improve by 40%.

What’s more, if you’re worried about carbide costs, you’ll want to use the whole cutter. Remember, runout uses certain teeth or flutes more than others. If you’re using carbide cutters larger than about a quarter inch in diameter, tool wear can get expensive quickly. There are significant carbide savings to be had by changing to a lower runout holder.

What many shops believe is acceptable runout is actually unacceptable if the shop wants to improve tool life. A manufacturer basing a tool holder purchase decision solely on the price of the tool holder may end up choosing a more expensive alternative, based on tool life and cost per cut, while sacrificing quality and accuracy. Runout accuracy pays. We’ve done the math.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

rahul thakur

Sat, 05/24/2025 - 08:11