What to Consider When Investing in Tooling for a New CNC Machine

-

Determine how the new tooling and machine fit into current production processes and shop culture.

-

Consider the intended use for the new tooling.

-

Even with a machine capable of high precision, accurate machining relies on workholding that ensures repeatability and stability.

-

Another thing to consider when choosing machine, tooling and accessory options is the growing need to incorporate shop floor automation in order to remain competitive.

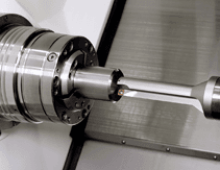

There’s a lot to consider when deciding how to tool up a new machine. The obvious questions—general tool categories and brands, for instance—are just scratching the surface. You’ll want to think about how new tooling will align with the new machine; how it fits in with current processes and shop culture; the specifics around the intended use; and the options you can’t live without—just to name a few. All this decision-making can be exhausting—but committing to a thorough tooling selection upfront is vital. Think about your tooling and machine tool as a symbiotic partnership: what affects one affects the other. Here are four key considerations.

1. How will the new tooling and machine fit into current production processes and shop culture?

All too often, programmers begin the tedious task of tooling up a machine after it’s already sitting on the shop floor. If operators weren’t included in the decision to purchase the machine, this can cause confusion and hinder productivity, because teams are playing catch-up to figure out how to work the machine into current processes. For the machine itself, this often comes down to the question of machine brand, category or control. If the new machine is something your crew is already used to, it’s often a more seamless transition.

On the other hand, getting a new machine can be an opportunity to level up your technology and processes and introduce tooling optimizations. During the shopping process, do some research on new tooling enhancements, trends and capabilities (see consideration #4 for example). By having a finger on the pulse of what's taking place in the tooling market—including tooling automation and digital enhancements—you’ll make more informed decisions and be better prepared to tackle any learning curves. When integrating new brands, technologies and processes, be sure to plan for more upfront communication and training to ensure things go smoothly.

2. What is the overarching goal—and intended use—for the new tooling?

This may seem like an obvious consideration, but oftentimes shops get stuck in a rut of going with what they know. What is the intended use of the tooling for your new machine? And what does the 5-year evolution of that look like? Are there other capabilities or applications you want to support in the near or distant future?

For example, we often see shops that are strictly committed to CAT tool holding systems. But if you’re looking to widen your capabilities, you might want to look into integrating HSK solutions as well, which are better suited for high speeds and micromachining capabilities.

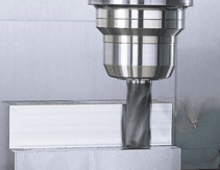

You’ll want to consider your workpiece materials, but perhaps more importantly: What is your philosophy on removing metal? Do you favor fast, high-speed, dynamic machining with high-feed mills? Or do you take a more old-school approach—deep, heavy cuts at a slower speed? Answering these questions will start to guide your spindle considerations and, ultimately, your tooling choices. Because your machine and spindle choices can limit your options when it comes to tool holders, it’s vital to consider tool holding needs upfront as you’re evaluating machine specs.

A good place to start is to ask the machine tool manufacturer if they offer a BIG-PLUS spindle—a dual-contact spindle system that offers increased tool rigidity and therefore more flexibility across a wider variety of cutting applications. More than 150 machine tool builders are licensed to integrate BIG-PLUS spindles into their machines, so chances are your machine tool partner of choice has that option. Keep in mind, however, standard V-flange tools won’t enable you to realize the full benefits of the system. Instead you’ll want to opt for BIG-PLUS tooling.

HSK is another option, but it’s crucial to consider intended use here. For example, an HSK 100 horizontal boring mill can deliver on heavy cutting as well as fine finishing. But with smaller machines and smaller taper sizes, roughing operations can get tricky. Here you have to be careful about projection and length, which can be tricky on smaller spindles.

Finally, the type of cutting application—drilling, milling, boring, tapping, etc.—will have an effect on your tooling choice. Our tip is to choose the right tool and toolholder for the specific application (versus attempting to find a more general purpose package). You’ll see better results and save money in the long term—with higher productivity, less tool wear and better finishes.

3. What are the types and sizes of your workpieces?

What might seem like an obvious question is more nuanced depending on the application. For example, in high-stakes aerospace jobs that deal with large workpieces but small, micro-machining cutting applications, you’ll need to balance the need for a larger machine that can accommodate very small tooling. The high-speed spindles on large machines can shorten the life of small cutting tools, so shops may want to consider air-driven spindles and other solutions that lessen tool wear.

With smaller tooling and larger machines, reach and rigidity are also concerns. The previously mentioned BIG-PLUS system is a smart choice for these applications because it offers that added rigidity. Rather than trying to build modular systems to overcome reach issues, angle heads can be a great alternative. These allow machinists to shorten the tool and come at the workpiece from a different perspective. And contrary to popular belief, angle heads are an option for five-axis mills and multi-axis mill-turn machines. In this case, make sure your chosen machine tool partner can support auxiliary systems like angle heads. Then, the machine tool builder can provide details on stop block positioning and configuration details. This setup is much harder to retrofit after a machine has been purchased.

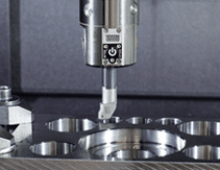

When it comes to workpiece type, accuracy is a big consideration. But contrary to popular belief, precision doesn’t hinge solely on machine specs. If you’re asking your machine tool partner, “How accurate can your machine make this part?” you may be missing the point. Machining accuracy is heavily dependent on workholding repeatability and reproducibility (R&R). For example, a machine tool partner can deliver on a required micron-level accuracy, but if the workholding can’t match, you won’t achieve the tolerance you need. Yet another reason you’ll want to consider tooling and machine specs at the same time.

4. What options will give you an edge?

Much like high-end cars, today’s machine tool manufacturers offer a wide range of options and customizations. Word to the wise: Bring your tooling partner in on these discussions! Oftentimes, tooling is discussed after the machines are already ordered—when it’s too late for a tooling partner to weigh in on options that could have boosted flexibility, productivity, precision and more. For example, 10 years ago, through-spindle coolant was a newer option; we would see customers in big-diameter drilling or boring applications who purchased new machines without this option. In hindsight, this crucial option could have saved them time, money and stress in the long run. On the flip side, customers may pay extra for high-pressure, through-tool coolant systems but not invest in the right tool holders to support that feature.

Another thing to consider when choosing machine, tooling and accessory options is the growing need to incorporate shop floor automation in order to remain competitive. Some ideas to consider include:

- Zero-point clamping systems help address the issue of repeatability of location from one fixture or workpiece blank to another, and the transfer of work between machines. This type of clamping also allows for multi-step machining without the need to unclamp the part. This increases speed and accuracy and reduces the labor and the risk of human error.

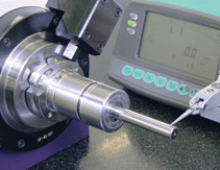

- Presetters can help keep spindles running by taking measurements offline, quickly and more accurately. This essentially acts as a shop’s communication hub and reduces the number of manual steps.

- Automated, intelligent tool management systems enable deep traceability and strong integrations with other shop floor technologies.

- Digital tools make adjustments in the machine easier, reducing human error, saving time and even enabling data capture and storage.

Involve your tooling partner early and often

Ultimately, knowledge is power and more brains are better than one. It’s never a bad idea to involve a trusted tooling partner early on in the machine tool selection process and identify smart ways to integrate machine specs and tooling packages. Have questions or need guidance? Get in touch today!

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.