Simplifying Tool Assembly

We talk a lot about some of the products we offer that handle tooling while they aren’t on the spindle—and for good reason. In order for your expensive tooling to perform at the highest level and for as long as possible, how you treat them when they aren’t interacting with the part—whether it’s storage, cleaning, set up or transport—is crucial.

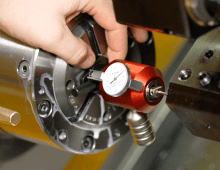

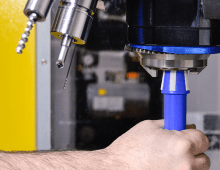

This week we’ll discuss a very simple, inexpensive product that can make basic tooling setups and other offline work a snap. The Tool Pro is a unique tool holding device that can be installed on a bench or tool cart. The head unit secures with 4 bolts, and the arm/adapter rotates and locks at every 45°, allowing convenient access and ergonomic assembly when tightening tooling components. Another benefit this handy device provides is a safe way for operators to setup tooling in a way that won’t damage expensive tool holders, shanks and machine spindles with “home-made” solutions.

Available for steep taper, HSK, polygon, and VDI tapers—tools are lowered into the tool pot and are automatically clamped in to place with a spring loaded pin that locates precisely into the V-groove of the tool holder, or other feature depending on the shank taper type.

In addition to the different taper styles it can serve, the Tool Pro comes in three variations to aid different set up requirements.

Standard

With an integral base and tool pot, simply depress the large gold button to permit the arm to rotate 360° degrees, with locking positions every 45°. Tightening torque can be applied in a downward motion, rather than horizontally. These units are dedicated to one taper type and size.

Vario

This quick-change system uses one permanently mounted base unit and multiple interchangeable adapters for different types and sizes of tool shanks in your shop. All other features of the Standard are incorporated.

Spin

Ideal for work on large-diameter tools, like swapping inserts on multi-pocket face mills, this version also allows 360° radial tool rotation while clamped. By engaging an index pin, tools can be locked at increments of 30°. All other features of the Standard are incorporated.

To see catalog numbers and detailed specs, take a look at our accessories catalog here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.