Presetters and Industry 4.0

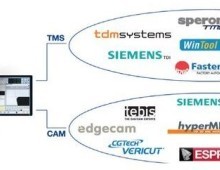

The dream of Industry 4.0 is for machines on a factory floor to be connected, able to communicate with each other. Maintenance can take place before breakdowns occur as data are exchanged again and again. Output is maximized, downtime minimized.

Makers of presetting systems were dealing with this basic concept. The systems keep track of available tooling as well as measures and inspects tools. This enables factories to maintain production. Now, presetters act as a building block of Industry 4.0.

“In the initial phase of presetters, you had a lot of screens,” said Robert Burns, our assistant product manager here at BIG Kaiser during an interview at the Eastec show in May. “We have been slowly able to streamline.”

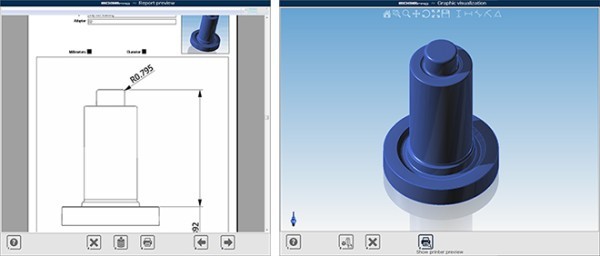

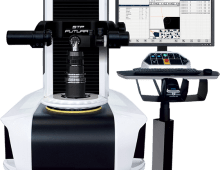

We displayed our STP Futura at Eastec. The machine has a large display screen which shows a more detailed display image of a tool, simulating a three-dimensional feel.

“This used to be a rather cumbersome process,” Burns said of presetting and measurement. Now, he said, systems are more automated.

Automated presetters have ensured precision. Tool setup is done correctly and there is the opportunity to take the data and assess everything.

“With the information provided, you can better forecast expenses,” said Burns. “Also, if you must back-track to find a quality problem, you can do that.”

Because of all this, presetters are emerging as part of Industry 4.0 strategies.

To learn more about our products, view our catalog or request a quote here and you’ll be contacted by one of our tool management system specialists.

This article is based on excerpts from an article that originally appeared in the July 2017 issue of Manufacturing Engineering and is used here with the permission of the publisher.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment