Vibration-Free Turning Isn’t as Difficult as It Used to Be

Vibration in a turning operation can be maddening. It leads to results that can be oh so close, yet so far away. It’s difficult to diagnose the cause. And it can be even more difficult to fix—reducing speeds, feeds, introducing sharper cutting edges or reducing depth of cut are all options, but each is a drag on productivity.

So, what to do? How does one maintain quality without sacrificing the all-important productivity levels in turning work? We believe we’ve got the answer.

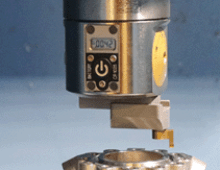

We’ve taken our Smart Damper technology, which has proven itself in some of the most challenging vertical, horizontal and multi-axis boring applications on Earth, and brought it to the world of turning. Packed with proprietary damping technology, the rugged boring bar single handedly helps limit one of turning’s most common and impactful challenges.

Here’s how it works.

It incorporates a passive damping mechanism that functions as a counter action by way of high resonance friction action. The patent-pending system’s damping capability minimizes the effects of high frequency oscillations, absorbing vibration effectively and allowing higher machining accuracy. It’s also designed with the capability of supplying coolant through the body directly to the cutting edge.

The Smart Damper boring bar features three modular insert holders, optimized for right-hand I.D. turning with ISO standard inserts at a minimum diameter of Ø1.58 inch. Metric bodies are available in Ø32 & 40mm, with inch versions at Ø1.250 & 1.500”. The general rule of thumb with this system is boring depths are possible at approximately 7xd.

For further details about the Smart Damper dynamic integrated damping system for boring, click here.

For further details about the Smart Damper dynamic integrated damping system for milling, click here.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.