Advantages of Hydraulic Chucks Over Shrink-Fit Tool Holders

In precision machining, selecting the right tool holder can make a significant difference in productivity and performance. One standout option is hydraulic chucks, which offer several advantages over other types, particularly shrink-fit holders.

Ease of use

Unlike shrink-fit tool holders, which require additional heating devices to clamp tools, hydraulic chucks provide fast and straightforward tool changes. No special equipment is needed—just a simple tightening of the wrench, saving both time and effort.

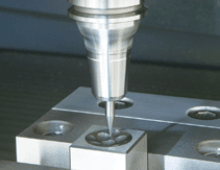

Superior accuracy and grip

Hydraulic chucks deliver exceptional runout accuracy, often as low as 0.003 mm, ensuring high precision. The hydraulic clamping mechanism provides uniform gripping force along the tool shank, minimizing the risk of slippage, even under heavy cutting loads.

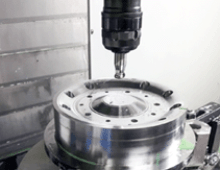

Vibration damping

The hydraulic system also helps absorb vibration, reducing tool wear and improving surface finish. This leads to longer tool life and less frequent tool replacement.

Versatility

With their ability to accommodate a range of tool diameters using reducer sleeves, hydraulic chucks offer flexibility, reducing the need for multiple holders.

Cost efficiency

While shrink-fit holders require regular investment in heating devices, hydraulic chucks eliminate this ongoing cost, making them more economical in the long run.

For manufacturers seeking efficiency, accuracy and reliability, hydraulic chucks are an optimal choice in a fast-paced industry where every second counts.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.