Manufacturer Makes Quantum Leap in Tapping Process Improvement

Located in one of the regions with the highest industrial activity in Mexico, Mecanizados Laguna, based in Gómez Palacio, Durango, has become a competitive company manufacturing metal components driven by a culture focused on detail and exceeding customer expectations.

To meet this goal, employees are always looking to improve manufacturing processes, knowing that significant improvements can be found in the details, as happened during the drilling process for one of their products. After an analysis with their supplier, they achieved a quantum leap in process improvement by simply changing one of the peripheral components: the tap holder.

At Mecanizados Laguna, they have diverse processes for various applications designed to manufacture special tools in materials such as carbon steel, stainless steel, engineering plastics (pyramid, acetal, polygar, Celeron), and other metals such as aluminum, copper, and bronze and brass.

The company manufactures specialized tooling for processes such as welding, machining, and Poka-Yoke type components, which is crucial for streamlining production on their customers' production lines. They also develop tooling for plastic molds for products as varied as furniture legs or special boxes for handling materials in the food industry.

Joel García, CNC machining manager at Mecanizados Laguna, explains that they have developed extensive experience in processes. “We started with Caterpillar, with whom we gradually established feedback processes to improve their processes. We have used our learning to improve the tooling and accessories we make for them and to make processes faster and safer for operators.”

The result is a culture of outstanding quality both in machining and services, with a focus on high standards and a zero-defect policy.

The value of good support

With the arrival of a project for an important client, they faced a challenge that, in addition to solving it, left them with an important lesson that now also supports their service and business philosophy.

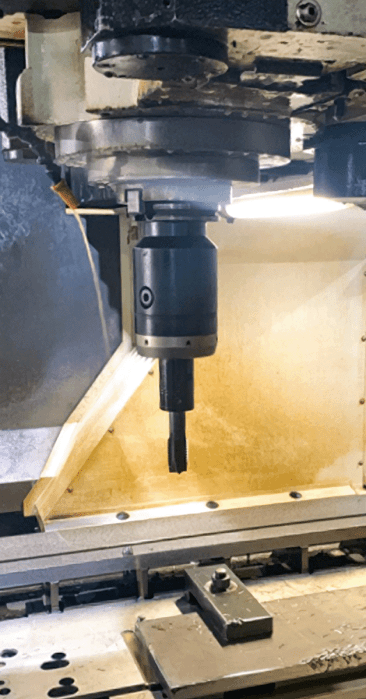

It is a piece of tooling with 26 holes that must be tapped with a step 3 m24 tap. “I think we started the project too fast,” admits Joel García. “We designed the setup for the part machining, but the tapers we chose didn't have the right depth. The limits were minimal, and we did not achieve the desired stroke for the hole depth, so we were under the risk of machine collision.”

To solve the problem, they took the part off the machine for the tapping operation. This process took more than 30 minutes and resulted in an out-of-tolerance thread. In addition, taps broke, tool wear was an issue, and cycle time and productivity suffered. They made some initial adjustments, but the performance was not adequate, and the taps barely reached 250 threaded holes before needing to be replaced.

The machining manager explains that they began to analyze options to streamline processes and improve production by their philosophy of meeting product and service quality goals. They looked for other opinions. That's how they came to the BIG DAISHOWA technical team and their distributor, AHNSA Tools.

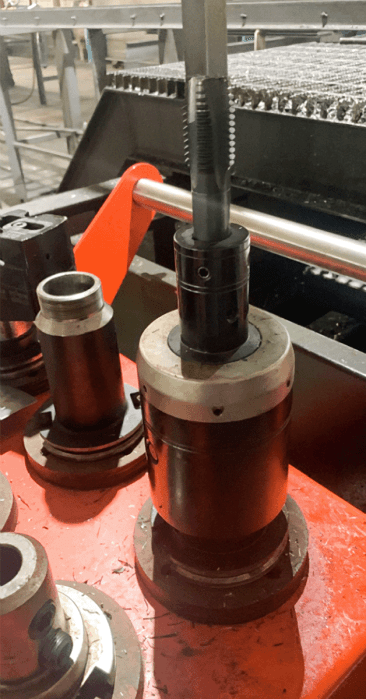

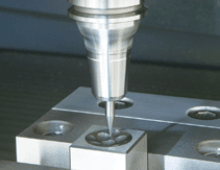

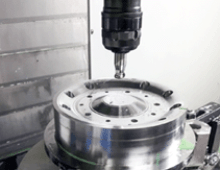

After reviewing the case, they concluded a different collet with better tool holding technology was needed. Therefore, they suggested BIG DAISHOWA´s MEGA Synchro tapping holder.

The results were immediate. With the MEGA Synchro tool holder, the life the tap went from 250 to 750 threads, the procedure became continuous, and costs decreased. "Over time, the process was reduced by 200%, and quality improved," says Garcia. "It was a relief, because our client was asking for a very tight tolerance."

With the new holder, the tapping process came back to the machine with a dramatic impact on the total time of the process, which decreased from more than 70 to just 35 minutes, tapping included.

Cultural change

Mecanizados Laguna's philosophy is focused on customer satisfaction. “We know that we have to invest in the best technology,” says García. With that in mind, they understood that it is essential to approach suppliers and receive other points of view on solutions for possible challenges in production.

“Most of the time, we think we are doing the right thing, but we are not always completely right. The engineers from BIG DAISHOWA and AHNSA Tools supported us and provided us with high-quality service, helping to find solutions that we could not find ourselves," says the engineer from the Comarca Lagunera firm.

With BIG DAISHOWA technology, they can project into the future. “Now we know that we can take more products from our customers with the tools and knowledge we have acquired, considering that we measure our manufacturing times based on our internal tools and processes. Today, we know that we can take certain risks that we couldn't before."

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.