It is really nice and very helpful information.

HSK 101: Everything You Need to Know About HSK Tool Holders

-

The HSK system, developed in Germany, features a hollow 1:10 taper with drawbar fingers, providing two points of contact for enhanced rigidity and precision, making it ideal for high-speed machining applications.

-

The HSK system includes seven types, such as HSK-A for moderate speeds and torque, HSK-E and HSK-F for high-speed micromachining, and HSK-T for multitask machining applications.

-

Unlike traditional steep-taper systems, HSK tool holders expand with the spindle, maintaining clamping force and contact at high speeds. HSK provides better precision and performance in high-speed machining environments.

With the rise of ultra-high-speed machining in the last several decades, the German hollow taper shank—hohl schaft kegel (HSK)—has grown in popularity in machine shops around the world. But even for those familiar with the HSK system, there are several things to know and consider. In fact, HSK is one of the most wide-ranging tool holding systems, with seven different standard forms. Let’s explore this unique interface.

What is the HSK tooling system?

The 1990s marked a significant era in the evolution of tool holding and spindle systems—including the advent of HSK. HSK was developed in Germany as a way to answer the growing call for higher-speed machining, which traditional steep-taper tooling couldn’t easily support. This innovation paved the way for speeds never before possible; today it’s not unheard of to reach speeds in excess of 50,000 rpm in certain micromachining applications.

Think of traditional steep-taper tooling (namely CAT and BT) as a massive locomotive: heavy but powerful and efficient when traveling more slowly. HSK tooling, on the other hand, is more like a fighter jet: light, aerodynamic and made for very high speeds.

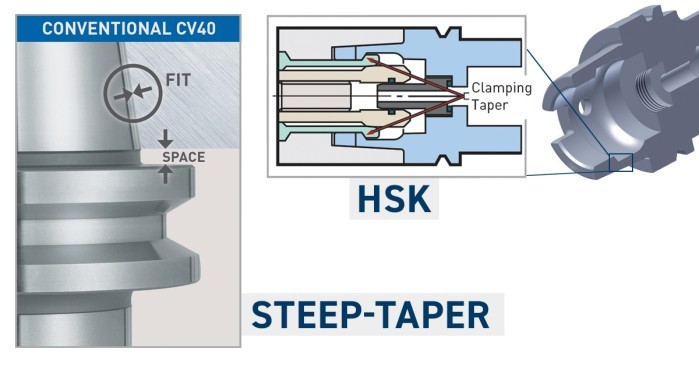

The issue with traditional steep-taper tool holders is that they do not expand/deform at the same rate as the spindle taper does at very high speeds, due to varying stiffness in the spindle and tool holder. This differential expansion causes the dreaded “sinking” effect, in which the tool gets pulled into the spindle. The HSK system, on the other hand, features a hollow 1:10 taper with drawbar fingers inside designed to expand outward with the spindle to maintain contact and clamping at high speeds. Thus, higher speeds actually improve the tool holder’s clamping mechanism and ensure proper seating. What’s more, the HSK system delivers two points of contact between the spindle and tool holder—both at the flange and the taper—for even higher rigidity and precision.

The 7 types of HSK tool holders

One of the benefits of the HSK system is its flexibility. The system offers seven different types of tool holders: styles A, B, C, D, E, F and T. The first four are typically for more standard applications; styles E and F are for the higher speeds, lower torque and smaller tools. For our purposes, we’ll be exploring the most common types, A, E, F, as well as the newest variation, type T. Learning the basics of each style will help you determine which is right for each application to ensure optimal performance.

HSK-A

HSK-A is the most popular and common HSK type. It is used for moderately high spindle speeds and moderate torque, making it suitable for a range of high-speed machining applications. This type is designated for use with automatic tool changers and features a V-shaped groove flange to facilitate this. The round-shaped keyway at the end of the HSK-A taper is a crucial design element for higher torque transmission. The tool holder’s plug bolt accommodates through-coolant as needed. In most cases, an HSK-A tool holder is suitable for general high-speed machining applications of up to 45,000 rpm that require moderately high torque.

HSK-E

Once you start getting into very high-speed micromachining applications, you’ll want to consider the HSK-E and HSK-F types. HSK-E type tool holders are designed to be almost perfectly symmetrical—with none of the notches and drive key slots seen in the HSK-A tool holders. This allows for extreme balance at very high-speeds—but only with very small tools at lower levels of torque.

HSK-F

HSK-F type tool holders are similar to HSK-E but with a few key differences. The taper on the HSK-F is slightly smaller than that of an HSK-E shank of the same size. This facilitates better contact between the flange and the spindle, thus taking the rigidity up another notch. For this reason, HSK-F holders may be ideal for moderate- to high-speed micromachining applications with low torque that require the highest level of precision.

HSK-T

HSK-T style tooling is specifically designed for turning in multitask machine applications. It is the newest standard for the HSK system, compatible with the HSK-A. The HSK-T style enables a tighter fit between the spindle key and the tool holder’s keyway for better accuracy.

The difference between HSK and other tool holders

Before the 1990s most metalworking employed the decades-old, ISO-standard, steep-taper interface (CAT or BT styles). But the demands on the industry—precision, higher speeds, new technology—were increasing rapidly, and this brought on a boom in spindle and tool holding system innovation. Within a matter of a few years, three new standards emerged:

- BIG-PLUS (developed in Japan by BIG DAISHOWA)

- HSK (developed in Germany by the DIN committee)

- Coromant Capto (developed by Sandvik Coromant in Sweden)

All three were designed to address issues with balance and stability that occur at higher speeds—by improving clamping force and spindle-tool holder contact. Let’s take a closer look at how the HSK system aligns and differs with other interfaces.

HSK vs. steep-taper design (BT or CAT)

Before we dive into this comparison, let’s make a distinction: Traditional steep-taper tool holders (most commonly BT or CAT) are single-contact—meaning the tool holder taper only makes contact with the spindle. The BIG-PLUS improves upon the steep-taper design by adding a second point of contact: flange-spindle contact as the spindle expands (more on that later).

Setting aside the unique BIG-PLUS system for a moment, let’s compare a standard (i.e., non-BIG-PLUS) BT or CAT interface to an HSK interface. Here are some of the key differences:

- Steep-taper interfaces feature a 7:24 taper ratio; HSK is 1:10.

- CAT and BT style spindles are larger and heavier and will expand at high speeds. Single-contact CAT and BT tool holders, on the other hand, do not expand at the same rate to maintain clamping; as such, the spindle pulls the tool holder in at higher speeds, which can negatively impact accuracy.

- HSK interfaces solve this issue with the hollow tool holder shaft and drawbar fingers inside, which expand along with the spindle to maintain contact and clamping at high speeds.

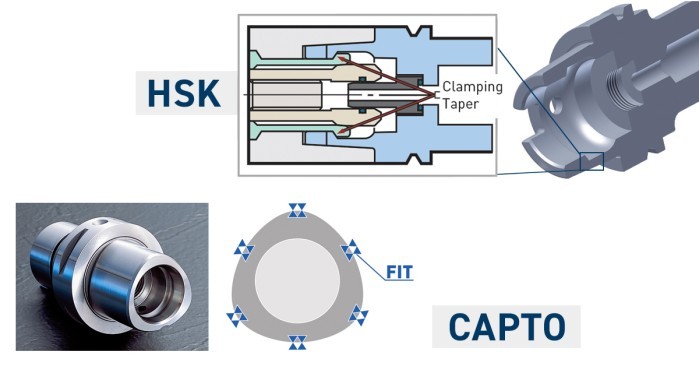

HSK vs. CAPTO

Comparing HSK and Capto (or HSK and BIG-PLUS) is a little more apples-to-apples—as all three systems aim to increase rigidity and balance at high speeds by providing two points of contact to improve clamping. But there are some key differences between Capto and HSK:

- Unlike HSK, Capto does not feature drive keys, but rather uses a tapered polygon with face contact to achieve torque transmission.

- Capto is typically used in multitask machining applications, whereas HSK is typically used more in milling (with the exception of the HSK-T style tooling).

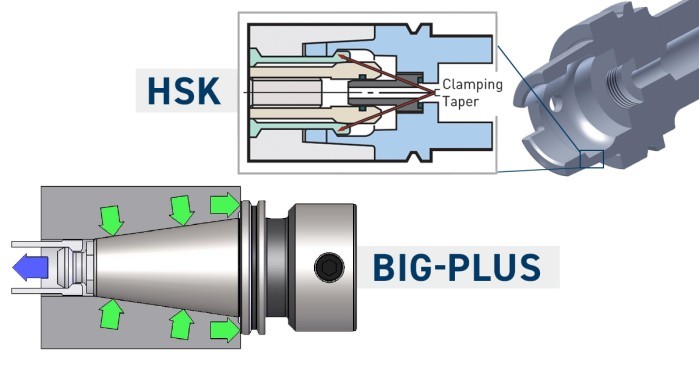

HSK vs. BIG-PLUS

Back to BIG-PLUS. This interface was developed as an alternative to traditional, single-contact, steep-taper systems. In that way, BIG-PLUS appears nearly identical to standard CAT and BT systems. However, there is one key difference: the surface of the tool holder flange delivers contact with the face of the spindle for a second point of contact (in addition to the taper-spindle contact). So if both HSK and BIG-PLUS provide dual contact and high rigidity, what’s the difference? Both systems leverage the natural elastic deformation that occurs in high-speed machining, but in unique ways:

- The BIG-PLUS system leverages the elastic deformation of the spindle to achieve the second point of contact. In other words, after clamping, the spindle expands until the tool holder flange makes contact with the spindle face.

- The HSK system, on the other hand, relies on the expansion of the tool holder itself. In this case, the drawbar fingers inside the hollow shank push out on the tool holder as speed increases. More centrifugal force equals better clamping.

- The BIG-PLUS system in general offers more flexibility for a wider range of applications; in fact, standard CAT or BT tool holders will work on BIG-PLUS spindles, and BIG-PLUS tool holders will work on other standard spindle interfaces. Just keep in mind that true dual-contact only occurs when BIG-PLUS spindles are used with licensed BIG-PLUS tooling. Still, having the flexibility of interchangeability is big.

- Its heavier mass and hallmark rigidity make BIG-PLUS ideal for deeper, heavier cuts.

- But for applications in which spindle speeds begin to reach peak rpm (24,000 or above), and for high-speed micromachining applications, HSK wins thanks to its lighter weight and the fact that higher speeds actually improve its clamping (thanks to the tool holder expansion).

Learn more about the differences between HSK and BIG-PLUS here.

Choosing the right HSK tool holder

When you’ve made the decision that the HSK interface is the way to go for a particular application, now comes the hard work. Optimal performance requires HSK spindles and HSK tool holders designed to work together and in accordance with industry standards. After that, you’ll size the tool holder to your spindle and determine the specific HSK tool holder type based on your tooling and application. But perhaps the most important consideration of this whole process is, which HSK tool holder brand? Here are some tips to keep in mind:

- Make sure tool holders comply with ISO 12164/DIN 69893/ASME B5.62 (the industry standards for HSK).

- Make sure the brand you choose has a wide range of HSK options. That way, you’ll have freedom to explore different types for different applications while enjoying the convenience of a single vendor.

- Choose a supplier who uses high-quality materials with optimal hardness and strength, and employs precision finishing and heat-treating methods in mission-critical areas (like the keyway and internal clamping areas) to ensure reliability and longevity.

- Work with a partner who has a strong reputation in the industry for expert application support. They’ll come in handy as questions arise.

BIG DAISHOWA is a pioneer in tool holding—and we lead the industry with one of the largest and most high-quality selections of HSK tool holders in the industry. Browse our full HSK tool holder selection here or get in touch with our application experts for advice and consultation.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Comments

Daniel Ceceña

Wed, 08/14/2024 - 10:01The text contains very useful information, they had never been able to explain to me where it made sense to choose an hsk instead of a big plus.

Thanks.

Jyrki Kiema

Sun, 01/26/2025 - 03:55I would be interested to know how much weight the HSK 100 and 125 can handle?

CHIRAG SUTHAR

Tue, 08/06/2024 - 06:53