Team Penske Increases Speed with Hi-Power Milling Chucks

{"preview_thumbnail":"/sites/default/files/styles/video_embed_wysiwyg_preview/public/video_thumbnails/-07sqg14mEc.jpg?itok=r96vJ73U","video_url":"https://www.youtube.com/watch?v=-07sqg14mEc&feature=youtu.be","settings":{"responsive":1,"width":"854","height":"480","autoplay":0},"settings_summary":["Embedded Video (Responsive)."]}

The full radial contact and extreme gripping force of Hi-Power Milling Chucks delivers the stability needed to increase spindle speeds by 20 percent in this application at Team Penske. Watch this short video with machine shop manager James O’Toole to see how he puts these high-performance chucks to work at the shop in Mooresville, NC.

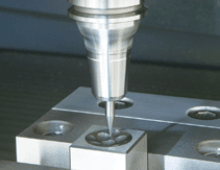

According to James, Hi-Power Milling Chucks have clear benefits over traditional tool holding methods like side-lock endmill holders. “The entire shank of the tool is contacted which increases stability and decreases runout,” he says.

There are also distinct advantages when using longer tools in heavy profile milling applications that may be subject to tool deflection and vibration. “BIG KAISER’s Hi-Power Milling Chucks flat-out deliver the performance we require here at Team Penske,” James said.

As a technical partner to Team Penske in the NASCAR series, BIG KAISER supplies tool holders, boring tools, workholding and tool measurement systems to the race shop. We also share our technical know-how and applications expertise to boost their productivity and part quality.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.