The End Mill Will Break Before it Pulls Out

For manufacturers using milling chucks, pullout is a major issue, particularly when machining HRSA’s such as titanium or inconel. In demanding applications, such as in the energy and aerospace markets, there is a need for guaranteed security against pullout – ensuring there is no costly damage to parts, or delays in manufacturing processes.

BIG KAISER offers a new solution with the Mega Perfect Grip milling chuck, a highly accurate non-pullout milling tool holder with fully concentric clamping and runout less than .0004″ at 4xØ.

Alan Miller, engineering manager at BIG KAISER, explains the product’s development.

“We took the existing standard of Weldon flats for end mills and ensured our high-performance milling chucks are now compatible with it,” Miller says. “The Mega Perfect Grip milling chuck product line accepts all industry standard Weldon flat milling cutters.”

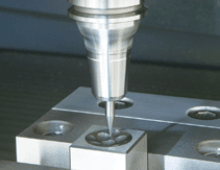

To assemble, insert the exclusive key grip into the Weldon flat of the end mill. Align the key grip with one of three key grip grooves inside the chuck body, and insert the cutting tool until it depresses a spring in the clamping bore. The spring functions to remove the gap between the key grip and the wall of the groove, and to provide a slight axial preload on the tool until final tightening is performed. Rotate the end mill approximately 20° until the grip stops securely against a stopping pin. This engagement prevents any slip under high torque. Finalize assembly by tightening the clamping nut until it contacts the positive stop of the chuck body.

The three key grip grooves in the chuck body also serve to provide channels for high volume coolant to reach the cutter, which is required in milling HRSAs to dissipate heat and to remove chips efficiently.

Final tightening of the clamping nut closes the milling chuck, making it impossible for the cutter to pull out. Tightening the nut using our Mega Wrench achieves dual contact between the nut and body for rigidity close to that of an integral cutter.

“Pullout can be a big headache when working with HRSAs – costing time and money, and hitting manufacturers’ profitability,” says Jack Burley, VP sales & engineering. “This innovative chuck solves the problem completely, combining innovation with ease-of-use and industry standards.”

The Mega Perfect Grip is available in BIG-PLUS® BCV50 and HSK-A100 for Ø.750”-1.250”, and HSK-A125 for Ø1.000” & 1.250”. The product is in stock and ready for immediate delivery from BIG KAISER’s North American headquarters.

For more information on the Mega Perfect Grip milling chuck, watch the video or browse the product brochure below.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.