Unilock Doesn’t Discriminate; Automate Loading of All Part Sizes and Shapes

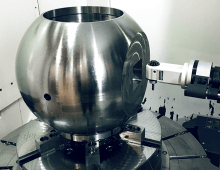

Reduced setup and changeover costs are among the many benefits of using a zero-point workholding system. Thanks to Unilock, our customers are achieving higher efficiency and agility related to workpiece handling. This comprehensive positioning and clamping system can be applied to almost any manufacturing or assembly process for a boost in productivity.

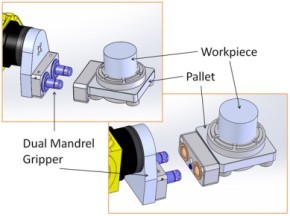

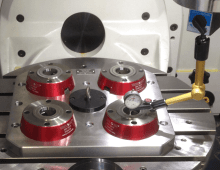

- The new Unilock ESA 120/70 automation chuck utilizes the standard Unilock clamping knob.

Now, with the new ESA 120/70 automation chucks, existing customers can add process automation to their list of reasons to expand their Unilock implementation. Until now, the standard knob program did not allow communication with the controller, preventing automation of fixture loading. Table integration of the ESA 120/70 chucks allows robots to pick and place fixtured workpieces into the machine. The system checks for workpiece presence, proper orientation and clamping, and then communicates back to the controller when the workpiece is in place and ready to be machined. On the flipside, when a part is finished and removed from the work envelope, the machine knows nothing is loaded and will not allow a new cycle to start until a new component is properly in place.

Of course cleanliness of mating surfaces is of upmost concern during automated loading. The top surface of the ESA 120/70 has self cleaning capability through an air blast originating off the chuck’s contact surface as the workpiece nears. Additionally, a slot was designed through the chuck that allows coolant or chips to flow out of the center clamping area and away from the precision locating features. For increased retention forces, the turbo assist feature boosts the clamping force to a max 1,870 lbs, compared to the max 660 lbs without it.

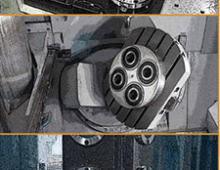

There are other new chucks in the Unilock portfolio that are true automation solutions and do not utilize the standard knob that the system is famous for. These automation solutions can be incorporated at the robot arm and the storage rack, not just on the machine table.

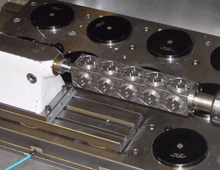

- The Unilock twin-gripper and mating adapter plate acts as the interface between the robot face and pallet edge.

Typically, a robot’s grippers have load restrictions related to part size or shape. Delicate and odd-shaped components, for example, are likely to require manual loading into the machine. Integration of an automation system allows a robot to load and unload complete fixtures, eliminating the issue of part size and geometry. A twin-pin gripper solution is what we offer. Sold as a complete assembly, the gripper is located on the robot arm or an adapter plate with two dowel pins. A coupling plate is them mounted to the edge of a pallet with the two female receivers.

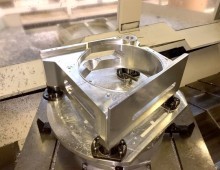

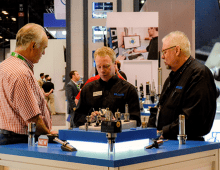

- A full automation solution is displayed at the BIG Kaiser booth at IMTS 2014. Unilock was used on the Fanuc robot, the pallet storage solution, and the Fanuc Robodrill machine table.

Integration at the rack allows for uniformed stacking of components on the pallet. This positioning consistency eliminates the need for an operator to preload fixture plates. Typically we recommend our self centering tapered/cone-shaped chucks that accept a clamping ring mounted to the bottom of a pallet.

Finally, table integration allows robots to pick and place fixtured workpieces into the machine, and just like the new ESA 120/70 system above, these systems also check for proper workpiece presence, orientation, and clamping. Communication back to the controller then relays that the workpiece is in place and ready for action.

Because the automation chucks are part of the standard Unilock program, customers can easily find an out-of-the-box solution to expand their current workholding program to include automation.

For more information about the Unilock workholding system:

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.