In Case You Missed It

We know you’re busy. You may have been finishing up a big project. Or you might have taken a vacation. Whatever the reason, here’s your chance to catch up. In case you missed it, we’re sharing our top blog posts of the past year.

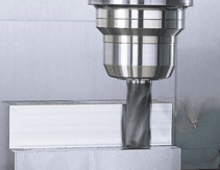

5. Comparing Tool Holder Performance and Price

Not all tool holders are created equal, which can present challenges for metalworking professionals. That said, choosing the right one for the work is clearly of critical importance to successful metalworking performances. For example, if rough milling in a tough alloy is the job, a side lock end mill holder is a sound choice in order to prevent pullout. On the other hand, if saving setup time is key to delivering on a job efficiently, a quick-locking hydraulic chuck may be better. Start your comparison.

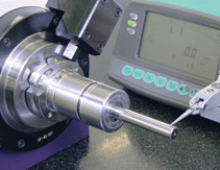

4. Assembling Your Tools Just Got Easier

The Tool Pro is a unique tool holding fixture for the assembly and disassembly of your tooling systems. The adapter of the Tool Pro can rotate 360º and lock in 45º increments. By securing the head at 45º increments, less force is required to achieve optimum torque transmission when tightening tooling components. Discover how the Tool Pro can make your job easier.

3. Powerful Machine Accessories: ChipFan and T-Slot Clean

When buying new equipment, it’s typical to spend a lot of time researching which machine offers the specifications and features to meet your needs. After all, you’re not only investing in the machine itself, but in the future and success of your company. To help protect your investment and maximize machine performance, we’re sharing a couple of machine tool accessories that may be missing from your shop: the chip fan and T-slot cover. Read how you can protect your investment.

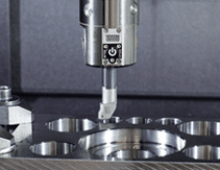

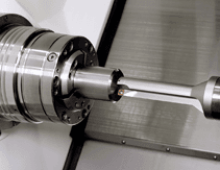

2. The Perfect Tool Heavy-Duty Rough Boring

Limitations of using milling tools to prepare holes for finishing become apparent as hole depth and volume increase. This is where BIG KAISER’s Series 319SW Twin Cutter boring head showcases its capabilities and can solve the issue along with virtually any other holemaking problem for the range of 0.787-8.000”. Learn how the Twin Cutter’s ability to take on heavier cuts allows your shop to be more efficient.

And the most widely read blog post of 2019…

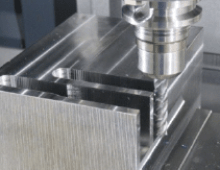

1. The Right Angle for Hard-to-Reach Features

Cogitic Corporation specializes in complex parts used in cannot-fail applications. As an approved supplier to the U.S. Navy, Cogitic was challenged with a new design of a large titanium ball valve component. The first challenge to machinability – beyond simply working in titanium – was securing the cylinder in the universal machining center and maintain access to the through-hole, which has an internal square key slot perpendicular to the stem hole. Learn how Cogitic machined those hard-to-reach features.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.