The Right Angle for Hard-to-Reach Features

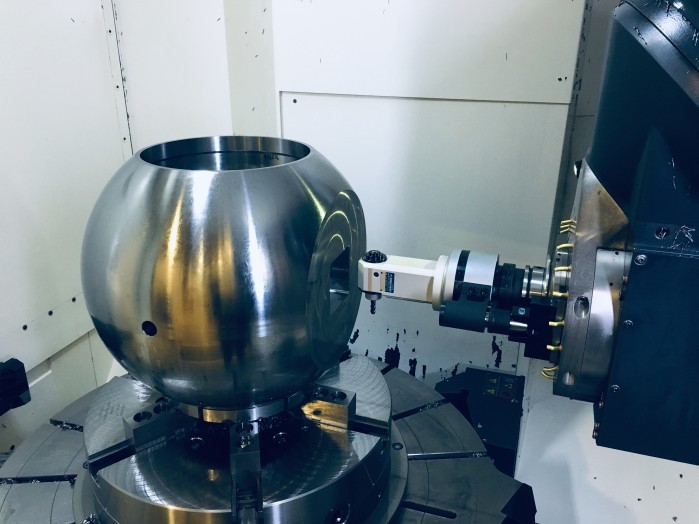

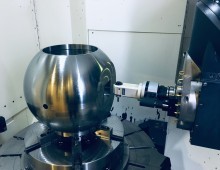

Cogitic Corporation is a Colorado-based engineering and manufacturing company specializing in complex parts used in cannot-fail applications. As an approved supplier to the U.S. Navy, Cogitic was challenged with a new design of a large titanium ball valve component.

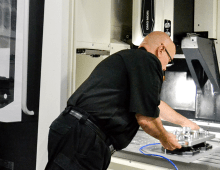

The first challenge to machinability – beyond simply working in titanium – was securing the cylinder in the universal machining center. It was also important to maintain access to the through-hole, which has an internal square key slot perpendicular to the stem hole. Even with the swivel-rotary table of the DMG MORI DMC 125, the key slot feature was difficult to access. Internal dimensions are very restrictive, with tight positioning callouts between the slot and the stem hole.

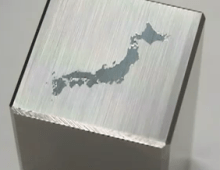

The solution was to machine custom-designed ID jaws to hold the 1,050 pounds of forged material, and use a right-angle head equipped with a short end mill to reach the 4.5-inch square slot from inside the cylinder. The finished part, a 21.5-inch titanium sphere, is reduced to 375 pounds during the roughly 40-hour machining cycle.

“The only other options would have been to outsource this operation to a shop equipped with wire EDM or move it over to a secondary operation on our VMC for broaching,” said Rory Dirck, manufacturing supervisor at Cogitic.

The right-angle heads from BIG DAISHOWA are often used to access hard-to-reach features on a workpiece (including IDs) that would otherwise be impossible without a secondary operation. This improves dimensional accuracy while reducing overall cycle time per part.

“The challenge both to interface the tool to the machine spindle and get a cutting tool down into the workpiece for that keyway feature. Every spindle is unique, but with our provided design they could quickly manufacture a stop block to spec and fully utilize the angle head,” said John Zaya.

“Initially we were worried about rigidity with this approach, but the BIG DAISHOWA right-angle head paired with high-efficiency toolpaths worked out perfectly,” Dirck said.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment