Who Made BIG KAISER’s Naughty or Nice List?

From all of us at BIG KAISER, we wish you a happy and safe holiday season. Every year around this time, we’re reminded that it’s thanks to people like you that BIG KAISER continues to lead and grow. Thank you for your business and your support throughout 2018.

While Santa is making a list and checking it twice, here at BIG KAISER we are also finding out what in the metalworking industry has been naughty or nice. Please enjoy this holiday-spirited post and hopefully it offers some valuable information or gets you thinking about ways to improve your processes in the upcoming year.

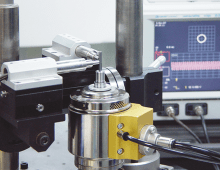

Naughty: High-Cost Presetting

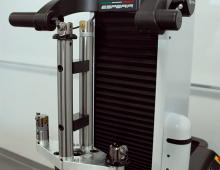

Nice: SPERONI ESSENTIA

The SPERONI ESSENTIA tool presetting and measuring system efficiently measures tools offline, allowing the operator to achieve full machine productivity. What makes this tool presetter unique is the concise and easy-to-use control specifically designed to optimize all tool presetting and measuring operations. The result - better parts, longer tool life and less spindle downtime.

Naughty: Unleveled Table

Nice: Level Master Wireless

The Level Master Wireless solves the tool table leveling challenge with ease, combining precision and simplicity. Using a leveling tool will not only make the machining process better, it will also help a machine last. The Level Master Wireless design makes it easy for one operator to level a table. The device uses optical level sensor technology and includes LED and buzzer indication to notify when leveling is complete. There is also a low and high mode switch for rough and finish adjustments.

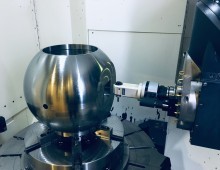

Naughty: Unlicensed Dual-Contact Tooling

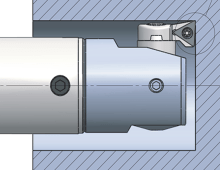

Nice: BIG-PLUS

Due to the popularity of BIG-PLUS®, many tooling companies, without a proper license agreement, gages, or manufacturing specifications and tolerances are offering dual-contact tooling. A conventional steep taper tool holder is supported on a reference diameter called the gage line. On the contrary, a

BIG-PLUS® tool holder is supported on the flange face, which brings remarkable improvement to rigidity.

Naughty: Tool Adjustment Errors

Nice: Digital EWE Boring Heads

The EWE Digital Boring Heads connect to a smartphone or tablet app to configure, monitor and track historical adjustments for multiple tools. The fully enclosed, compact and rugged design allows reliable operation, even under extreme cutting conditions or with coolant. Color-coded dimensions give operators a visual cue when the tool is back into tolerance and ready to continue production, which decreases the risk of adjustment errors.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.