Take Advantage of Your Shop-Floor Data

“How can you get the most out of an investment for your shop?” is how our product manager, Doug Sumner, begins the conversation in a recently featured article in the Fabricating & Metalworking magazine titled, “Tool Measuring Systems and RFID Working: A Powerful Combination.”

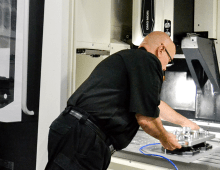

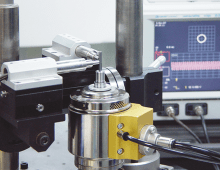

In the article, Doug shares how one of the important areas of focus in the manufacturing industry is how to get the most amount of parts manufactured with the least amount of waste—both in terms of time and material. More and more, the answer comes down to analyzing and understanding your data, and a presetter, for example, can supply significant information.

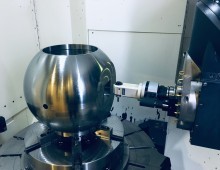

“Take a moment to think about if you had data on a tool’s dimensions, usage and if a certain assembly was running out,” states Doug. “Now, imagine how you could use that information to expedite setup time in the tool crib, reduce scrap and waste, even track what’s happening on the floor. That’s the kind of information a tool presetter helps you capture and leverage.”

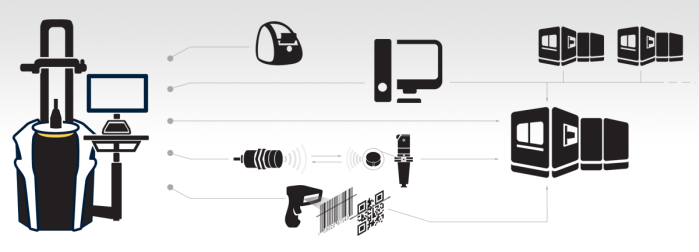

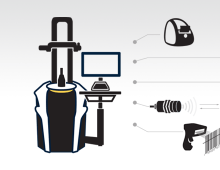

Doug continues the discussion by focusing on RFID as a means for transferring this data gathered. RFID is an interesting one, because a tool assembly’s data can remain with the tool on an embedded chip. It’s probably the most accurate means of transferring tool data, as it eliminates a ton of room for error and allows you to track the life, or expected obsolescence, of a cutting edge or holder.

As Doug mentions toward the end of the article, “While tool presetters may be an upfront investment, it’s one that can get more production out of the machines you presently own—which is well worth it. Not to mention they can make your factory floor smarter, streamlined and way more efficient, which will help keep your business competitive as new technologies emerge.

To read the full piece, please click here. To learn more about our presetter offerings, follow this link.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.