Q&A with BIG KAISER President and COO Jack Burley

After more than 30 years at BIG KAISER, Jack Burley was recently promoted to president and COO. Here, he shares some of his observations over the years, predictions for the industry and his vision for the company.

Q: What has changed about how things are done in the industry during your 30-plus years at BIG KAISER?

A: I remember starting a design with the plan view, then building the side view, top view, etc., and having to visualize for myself necessary clearances and angles to make the tool work. I memorized certain formulas for the design check, weights and balance, etc. but then new CAD tools displaced this need.

I understand this makes life easier and more predictable, but it has taken some of the artistry out of tool design and tool building. It’s a similar scenario of the machinist compared to a CNC programmer—one uses sine plates and levers, the other uses G codes and CAM to generate tool paths to accomplish the same result.

Q: Technology certainly has had an important part in advancing the industry. What’s next in the world of machining and tools?

A: The growth of multi-axis or 5-axis machines is seeing rapid expansion into many shops due to higher productivity and accuracy. With this equipment becoming more of the norm, many adjustments to shop rates and worker potential will be realized. The standard practice of hiring a machine operator will be replaced by hiring an engineer to program, set up, and operate multiple pieces of equipment and automation. The shop-floor engineers will be highly skilled at adapting new technologies, building digital twins, and documenting the process with AR (augmented reality). Setting up tools offline with automated systems and moving them onto the machine without human interaction is very possible, and likely to be in everyone’s not-so-distant future.

Q: in 2020, BIG KAISER Precision Tooling celebrated its 30th anniversary. What role does BIG KAISER play in the industry?

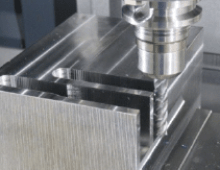

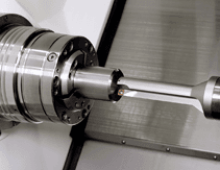

A: BIG KAISER, as part of the BIG Daishowa group, is strategically positioned and capable of making the best tooling systems and measuring equipment in the world. I know this may be a bold statement, but I truly believe that there is no other company that offers tooling to the market with the accuracy and variety of BIG KAISER. False claims of accuracy and repeatability are not in our vocabulary. Every tool we make must pass our stringent quality standards—a standard that others claim but only we deliver. We will never compromise on our quality standards and will always be the highest precision tooling company available to the market.

Q: You’ve been with BIG KAISER since it opened its doors and have weathered the ups and downs of the industry from recessions to 9/11 and, most recently, COVID. What is your vision for the future of the company?

A: Many people have speculated that as businesses adapted to “a new normal” with COVID restrictions in place that traditional ways of doing business, such as the sales call and in-person meetings, will no longer be necessary. I can agree to a point, but humans are social beings. The casual business call to check in and see how a customer is doing and how the products are working cannot be replaced by a virtual meet and greet. Seeing products up close and personal, making direct contact, and getting to be with each other is important and will return someday.

Having said that, the mother of invention is change spirted by curiosity and the desire to make life easier. On the manufacturing side, automation of how we do things easier has to be constantly evaluated and analyzed to see if the new technology fits the need. Software can be a great tool at making our daily work easier, but it can come at a cost of losing touch with reality, so it’s important to understand how it’s used and to be mindful of the data.

I want technology to play a role in what we do and how it’s done, but only if the outcome means more opportunity with the same employees. Our company and our products must evolve as technology does; the new technology has to be easy to adapt and justify the increased cost. We are working on products that can communicate wirelessly with other equipment, this ability will reduce errors and increase productivity and improve quality control.

Q: In closing, what message would you like to share with current and future BIG KAISER customers?

A: We have maintained “Higher Performance Guaranteed” for almost 20 years, and we will continue with that tradition as it addresses our core belief in our products and technical advice. It is our responsibility to maintain our product quality and capabilities so that our customers have the confidence, assurance and trust in our tooling to do the job right the first time and every time.

New sources of data for successful implementation of our tools and measuring equipment continues to evolve and be more accessible with a minimal amount of obstacles or personal intrusion. CAD models, wireless transfer of data, and cutting data apps are all available to support customer needs and increase their overall productivity.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.