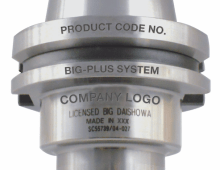

Tracability is Paramount – Look for the License

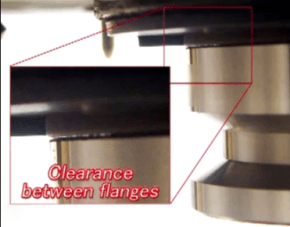

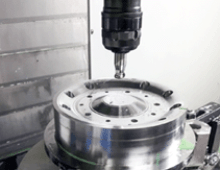

Note the clearance between flanges on this competitor's unlicensed tool holder.

It took more than 50 years of evolution for the 7 to 24 shank to reach its pinnacle.

- 1939 – The dawn of the 7 to 24 taper shank age

- 1969 – The BT shank was standardized in Japan

- 1992 – BIG-PLUS® Spindle System developed by BIG Daishowa

The BIG-PLUS® spindle system is strictly controlled by machine tool and spindle manufacturers licensed by BIG all over the world with the exclusive master gauge and measuring equipment BIG manufactures and maintains. All of the master gauges have traceability to the original grand master gauge held by BIG Daishowa. BIG’s original AI code chip is embedded in these master gauges to consolidate the management of accuracy and calibration data.

But be wary. Tool holders without the stamp of “BIG-PLUS Spindle System – Licensed BIG Daishowa Seiki” are on the market. Unlicensed tooling companies are attempting to manufacture and market tool holders for use in BIG-PLUS® spindles that do not have traceability to the grand master gauge held by BIG Daishowa, and some of these tool holders provide neither face contact nor taper contact. Purchasers of these unlicensed products risk problems arising from performance, premature spindle wear, or accidents.

This video explains the difference, and what that difference can mean to you in terms of time, energy and productivity.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.