Tooling Upgrade Wins Races for Team Penske

On race day, everyone sees the race on TV, but there’s another competition going on back at the shop that most people never see.

A racing shop’s work is unpredictable and lead times are short. Rules change from week to week—often significantly—requiring different parts be added, removed or modified. Each week’s race track also requires similar adjustments, not to mention the real-time performance feedback from the track during race weekend. In post-race debriefs, engineering and management devise plans to make race cars track-ready by the next weekend. Decisions must take into account performance factors such as weight, balance, stiffness and aerodynamics of the race car.

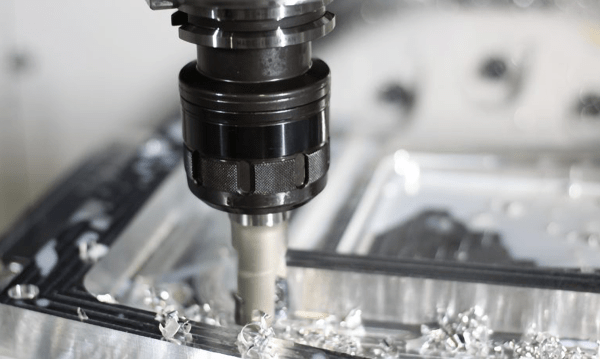

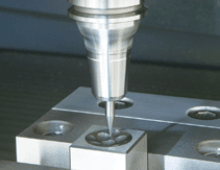

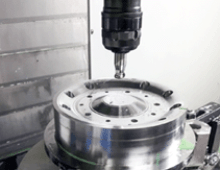

Team Penske’s machine shop serves multiple drivers on the Monster Energy NASCAR Cup, NASCAR Xfinity, Verizon IndyCar and IMSA DPi series circuits. Constantly optimizing processes and equipment to achieve an advantage over other race teams, Team Penske adopted tooling improvements based on its decision to expand usage of the BIG-PLUS spindle interface and tool holders.

“One of the biggest things you can look for in tooling is versatility,” says James O’Toole, machine shop manager for Team Penske. “With all the different holder types that BIG KAISER offers, we can standardize our magazines to a high level, moving from one job to the next seamlessly and with reduced setup times.”

Read the full article here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.