The Tooling Problem Solvers

My career with KPT KAISER started 30 years ago this month in July 1990. I knew Chris Kaiser as we had worked together when I started in this business working in Upstate New York, and he was our representative for the Midwest. We had already shared some memorable times, and I was hired by him to help start the company’s engineering department.

When I arrived in Chicago, I was the 4th employee, so additional responsibilities to get the company up and running quickly included sales, inventory and marketing needs, such as the catalog and our first IMTS, which was just two months away. We had to identify how to market our new company for the North American market.

It’s not often that you get the opportunity to start from scratch, a clean slate as they say. Everything was brand new: the building, equipment and inventory. Most importantly though, we all shared a strong desire and commitment to Heinz Kaiser’s vision for KPT: To make the Kaiser CKB boring tools #1 in North America.

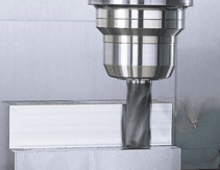

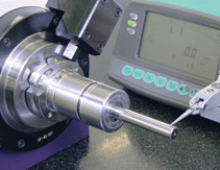

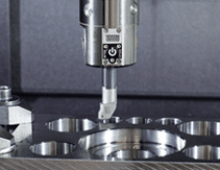

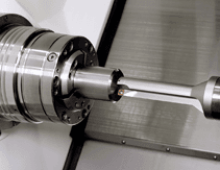

The common boring tool used by most shops here in 1990 was the same type of tool used since the 1950s. The tools were not built on a modular connection; some didn’t even have indexable inserts to replace worn cutting edges. Diameter adjustments were difficult and unreliable, usually influenced by the locking system. Twin cutter rough boring tools were still not widely used or even known, and some boring processes required three to four tools for a single hole.

We were ready to introduce our proven technology and tools for increasing productivity. However, change is never easy for anyone, especially customers who have always done it their established way. Our objective was to demonstrate change.

Changing established habits meant we had to prove ourselves by testing and solving the most difficult tooling issues presented to us. We were creative, flexible, adaptable, and most importantly, ready to take on any problem, despite the risks involved.

We traveled all over North America and tried to do what others would not. We may not have succeeded the first time, but we promised to come back with a different approach or idea, and it usually worked. From these early experiences, we advertised ourselves as “The Tooling Problem Solvers” with a challenge to “give us your toughest problem,” a theme we carried into our first IMTS.

After IMTS 1990 was over, the engineering team had many requests and problems to solve. Most of them involved very deep holes with interrupted cuts on equipment that was past its prime, but that was ok. Backed by an executive team that fully supported us, we were confident that we had the best tools in the world and could get it working better than expected.

I still fondly recall those early days at KPT. We’ve grown since then, not only in the scope of products we offer, but also in our commitment to make a difference for our customers.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.