Six in One Hand, Half Dozen in the Other

There’s more than one way to skin a CAT…or should we say HSK in this case.

Modular systems afford you the ability to take standard components and configure them in a way that meets the same criteria you had been looking for, even though the components you had spec’d out were not in stock – or even an option – at your favorite vendor’s warehouse. Not to mention, it’ll save you money.

Consider the following customer story, from one component manufacturer serving the Armed Forces:

Since delivery time was of somewhat importance, and the tool holder need was somewhat odd, the customer sought out this challenge thankfully with an open mind. Afterall, what were the chances of finding multiple pilot-diameter shell mill holders, with an integral HSK-F type shank, in a longer than normal gauge length—and already designed as a standard solution? Not great—unless he was open to a modular solution.

So the “ends” of the situation were as follows:

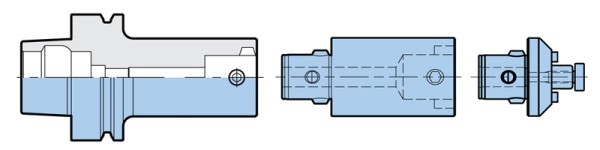

He needed an HSK-F63 interface, and needed one shell mill adapter with a ¾” pilot, and one with a 1” pilot.

Fortunately, because of the extensive variety of modular KAISER components, there’s more than one path to meet our customers’ needs.

And the “means” were as follows:

Our customer, on his own, perfectly spec’d out a complete solution – shank, extension, and two shell mill adapters, all with KA6 connections. Unfortunately, as it turned out, the uncommon HSK-F63 shank with KA6 was a special order—6 weeks delivery, which was not really an option for him. But, thanks to our veteran leader in the inside sales pit, Andrea Distelhorst, by suggesting a KA5 assembly instead, we were able to get him exactly what he needed as a standard offering. Unfortunately, we still hit a small roadblock. One of the pieces had to be brought in on our next shipment from our overseas partner BIG Daishowa, who is a licensee of KAISER. Still, this solution cut the delivery time by 4 weeks, which was more than acceptable.

Plus, with this modular system, the customer was able to effectively purchase two different tools, but with only one shank. He can now switch between the ¾” and 1” shell mill adapter using the same holder and extension as needed. An integral solution with those specific “means” would not have only been considered specials with nearly every tool holder manufacturer—meaning long lead times—they would have been dedicated tools with no future flexibility. Our KAISER modular system fulfilled an immediate and future need, and became a less expensive solution all the way around.

But these types of solutions aren’t always readily apparent. That’s where committed and well trained customer service people come into play. With years of experience, inside salespeople at BIG Kaiser know how to offer pragmatic, alternative and cost-effective solutions to get customers exactly what they need.

At the end of the day, the customer expressed his thanks, saying “I want to thank all of you for working so diligently with us on this project. I am impressed with how quickly your team responded back to us and pulled information together to resolve the issue. We appreciate the excellent support that has been provided to us so, in turn, we can meet our schedules for our Armed Forces customers.”

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment