How the Right Tool Holder Can Extend Tool Life

-

Managing runout with the right holder, such as the MEGA ER Grip collet chuck, can significantly improve tool life by ensuring even tool engagement and reducing wear through more uniform load distribution across all flutes.

-

Collet-style holders enhance accuracy and versatility for high-speed machining, with specialized bearing nuts and precision-engineered pullstuds and collets ensuring minimal runout and maximum tool life.

-

High-speed and long-reach machining demand holders that offer exceptional rigidity, balance, and precision, with hydraulic chucks and dual-contact holders providing stability and efficiency to extend tool life in challenging applications.

If you’re looking for fast, easy return on investment, improving tool life is one of the best options a metalworking operation has. While many look to speeds, feeds, proper programming, and chip thinning or advanced insert grades and coatings for relief from wear, how the cutter is held plays a fundamental role in getting the most out of consumable tools. Among the variables in a cycle, the holder is more of a constant, making the right one invaluable to tool life across multiple operations.

Choose holders that manage runout

Regardless of application, one of the most important factors in limiting wear is constant, even tool engagement with the part, every tooth bearing an equal load. With runout in the equation, or variation in the diameter of the cutting tool at certain points as it rotates, tool life inevitably suffers.

As flutes contact the part differently, each performs and wears at different rates. It’s an inefficient use of consumables. There is a simple way to estimate the impact of runout on your tools. The One Tenth = 10% Rule states that one tenth of runout will increase or decrease tool life by 10%. In other words, if five tenths of runout is reduced to one tenth, tool life should improve by 40%.

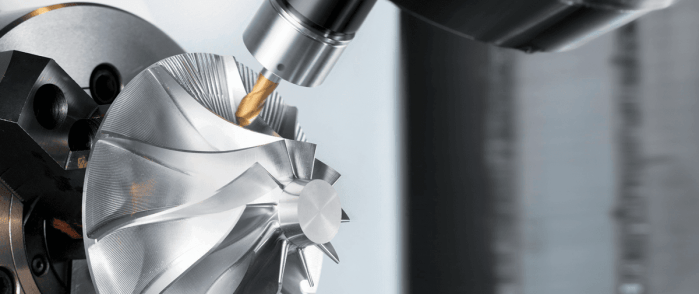

Just how much of a difference can runout make? We tested it: the exact same .118" diameter carbide drills with runouts of .0008" and .0006", respectively. The drill with less runout made 2,300 holes in a steel workpiece .590" deep; the other, just 800. The MEGA ER Grip collet chuck has excellent clamping force, concentricity, rigidity and balance at high speeds. It clearly demonstrated the savings in both tool life and tool-change downtime.

With that in mind, let’s look at some common holder scenarios and ways to maximize tool life for each.

Improving tool life with collet-style holders

Collet-style holders are popular for their accuracy, high-speed capabilities and versatility. The collet nut allows for more points of contact and a flexible gripping range when compared to other chucks. These tools are not immune to runout and uneven wear, however. For one, the higher the length-to-diameter ratio and mass, the more of an effect on the holder as it spins. A few other ideas to improve tool life include:

- Choose bearing nuts for smoother clamping, lower torsion, better gripping force and less collet wear. We make specialized nuts available for efficient coolant supply or protection of small holder components that can cause runout.

- Use pullstuds made of strong metals to resist deformation and maintain accurate locating. Our pullstuds are all built with through-hardened H13 premium tool steel and precision ground features.

- Remember, collets collapse onto the chosen tool, not expand. The size on the collet is usually its maximum diameter. A shallower taper of the collet and thick-body design improves concentricity, helping to reduce chatter and deflection. Each of our collets is inspected for 100 percent concentricity and guarantees runout within .00004" at the nose.

- Slimmer designs reduce the need for extensions in the case of interference. The high speed and precision a single tool can deliver is ideal for small mold making.

See some of the other considerations the keep in mind and more about how we build our collet-style holders a little differently, to make preserving tool life easier.

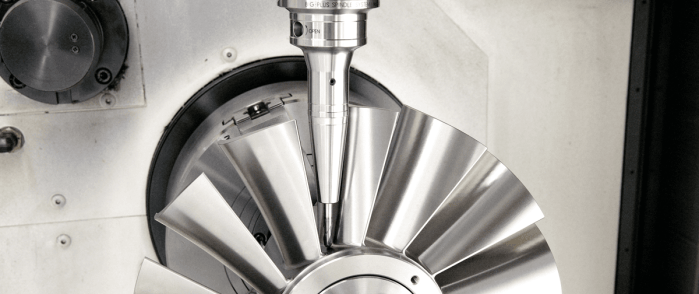

Improving tool life with high-speed holders

High-speed machining is a whole different animal. When speed increases, the forces pushing the holder off center increases too. This runs the risk of uneven radial forces on the cutter and, in turn, premature wear. To achieve efficient tool life, proper finish and productivity in high-speed work, holders need to be as rigid, compact and short as possible to keep the whole assembly stable. While there are unique factors when considering holders for high-speed machining in general, when tool life is a priority, consider these specifically:

- The higher gripping force the better. Extra contact length in the internal taper of the chuck enhances this, while a shallow collet taper and micro-mirror, ground-finished surfaces improve concentric force and help with balance.

- Holder balance matters most in high-speed applications. Instead of the commonly referenced G2.5 issued in 2003, consult ISO 16084 provisions for the definition of maximum imbalance for different applications. This 2017-issued standard was developed specifically for rotating tool systems and takes into account the spindle-tool interaction and load.

- Dual-contact holders maximize all-important stability at high speeds, keeping cutters on the center line by making flush contact at the taper and face of the spindle.

Improving tool life with long-reach holders

Like high-speed machining, long-reach scenarios add a whole new set of geometrical and physical influences to consider. Finishing off those deep pockets and cavities is always a challenge. Put simply, the farther the tool does its work from the spindle, the more room there is for error and/or uneven wear. Some things you can consider in order to preserve tools during long-reach work include:

- Consider hydraulic chucks. In addition to their natural vibration damping that helps make cuts efficient, relatively small nose diameters are ideal for reaching into pockets and 5-axis machining.

- Always balance holders as a complete assembly. Factory-balanced holders are often inadequate for long-reach applications. For instance, CAT and BT holders should be balanced with the retention knob and cutting tool in place, and HSK holders with the coolant tube.

- Don’t overlook maintenance. Keep holder bores clean and test gripping force regularly. Tooling and spindle cleaners are fast, easy and safe for operators to use regularly.

While we haven’t covered every scenario, the right holder is an effective counter to consumable waste. (Carbide isn’t getting any cheaper.) Cost per part is another solid way of measuring the benefit of an improved tool holder. Getting more tool life from a single tool means more parts from the same production cost—and lower cost per part. Even bigger picture, shorter cycle times have more impact on lowering the cost per part than even the machine or operator burden rates over time.

So, before you put your money in another, less efficient investment, consider how tool holders may be able to pay big dividends for over time. Explore our entire lineup of high-performance holders, from hydraulic chucks to basic arbors, to find your next solution.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment