BIG KAISER’s 10 Most Useful Articles of 2020: Part 2

In case you missed it, be sure to read part 1 of this post for a glimpse at five more articles from leading trade magazines that are jam packed with some of our best advice. Let’s dig into five more, covering topics like the differences between types of milling holders, 5-axis work and micromachining.

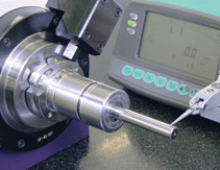

Improving Tool Holder Performance

BIG KAISER author/contributor: Alan Miller, engineering manager

Publication: July 2020 edition of Gear Solutions

Key quote: “The four critical requirements for tool holders are clamping force, concentricity, rigidity, and balance for high-spindle speeds. When these factors are dialed in just right, there’s nearly no chance of holder error and considerable cost reduction is achieved thanks to longer tool life and reduction of down-time due to tool changes.”

Something you’ll learn: why all dual contact holders are not the same and the marking to look for to verify true BIG-PLUS dual contact.

Read article now

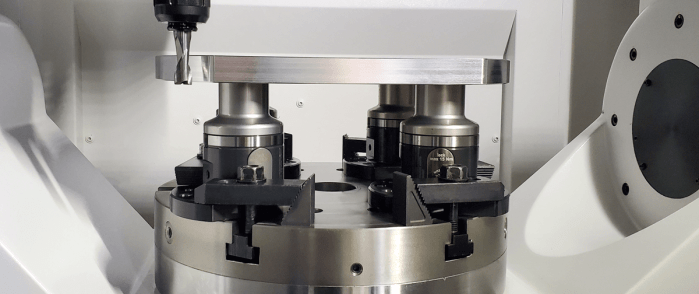

Workholding Considerations for 5-axis Machining

BIG KAISER author/contributor: Jack Burley, VP of sales and engineering; John Zaya, workholding product manager

Publication: August 2020 edition of Modern Machine Shop

Key quote: “Don’t think that your fixture has to be designed around the part. Holding could take a very different form. Take a step back from what you’ve always done and reconsider your options. Now you have a lot more flexibility with the machine, so you need to consider more flexibility with the fixture.”

Something you’ll learn: the role machine size plays in 5-axis work and adjusting for the overhang issues of dovetails.

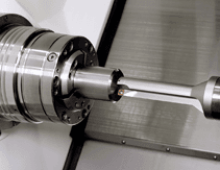

Why Machinists Should Take Bending Moment as Seriously as Vibration

BIG KAISER author/contributor: Jack Kerlin, applications engineer

Publication: July and August 2020 editions of Fabricating & Metalworking

Key quote: “Torque is typically used to describe a force that’s twisting a shaft or rotating body – the distance being the radius of the shaft/body – whereas bending moment is more general. It usually describes a force acting on the end of an unsupported beam, causing it to bend like a diving board. Both are examples of force applied at a distance and both behave according to the law of the lever.”

Something you’ll learn: since neither the machine nor operator can monitor the bending moment, we share how to assemble the best tooling combinations for avoiding it.

Read part 1 now

Read part 2 now

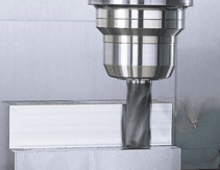

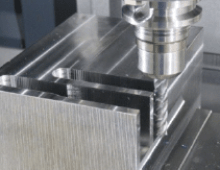

Important Advice for Milling Holders

BIG KAISER author/contributor: Alan Miller, engineering manager

Publication: October 2020 edition of CNC West

Key quote: “Milling chucks provide substantially more gripping force than a collet. Runout, is reduced compared to collet chucks, but is still better than double the performance of side-lock systems.”

Something you’ll learn: the strengths and weaknesses of the five most commonly used holders for milling and applications they’re best for.

Read article now

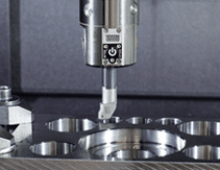

Yes, You CAN Micromachine with a Standard Machine Tool

BIG KAISER author/contributor: Kevin Spring, sales engineer

Publication: November 2020 edition of Fabricating & Metalworking

Key quote: “While just about any shop can drill a quarter-inch hole and use an end mill, how many can micromachine? Based on my experience, I estimate about 10%. There’s huge opportunity out there.”

Something you’ll learn: how to generate the power and speed needed on a standard machine to enable micromachining tools to perform well.

Read article now

Again, if you missed part 1 of this post, check it out for more of our best advice that you can use around the machine shop.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.