Accessories Aren’t Just Luxuries Anymore

Just because your tried-and-true accessories for machine tool installation and inspection have gotten you this far, that doesn’t mean you shouldn’t be looking for better solutions. Every second of down time means money wasted, and so does a machine tool not performing up to its potential. Ultra-high precision accessories are at your fingertips and are a wise investment for your tool box. An eyeball test on a bubble level is no longer good enough. It’s time to re-evaluate your methods and tools for install and maintenance.

Enter BIG Kaiser, a different kind of tooling partner

Most major tooling and carbide insert manufacturers focus their R&D on milling, drilling and turning products. BIG Kaiser, along with our strategic partners, has quite a bit of that stuff in our portfolio too—plus boring tools, tool holders, collets, zero-point workholding, angle heads, spindle speeders, tool presetters and a ton of unique, time-saving and accuracy-enhancing accessories.

Some of our accessories for machine tool installation & repair—or even for preventative maintenance to keep your machines running smooth and operating at top performance—include:

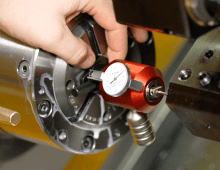

ATC Alignment Tool

ATC Alignment Tool – Ensure alignment between the spindle and ATC gripper to avoid spindle damage. The plug features a built-in stylus that determines the eccentric direction when rotated. The values are displayed on a 10 micron/div. dial indicator for easy adjustment.

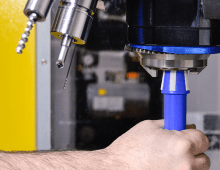

Dyna Test

Dyna Test – Precision test arbor to identify potential spindle runout problems. Certified bar tolerances include 1-micron roundness, 2-micron runout, 3-micron cylindricity, 5-micron diameter tolerance, AT1 taper contact and a roughness of .6μm Ra.

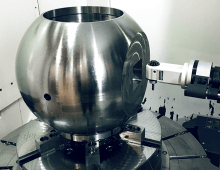

Dyna Force

Dyna Force – Accurately measures and identifies potential problems of spindle retention force. The digital measurement unit displays the clamping force with an accuracy of .1kN (22.5 lb-force).

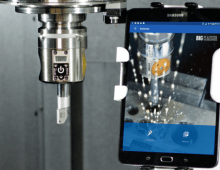

Level Master

Level Master– Simultaneous 2-axis detection with LED and buzzer indication for leveling machine tool tables. The optical level sensor technology allows for 10-micron-per-meter precision.

Think of it this way: If your competitors aren’t taking advantage of these nifty accessories, you have an opportunity to distance yourself from the pack. If your competitors are using them, they’re slowly but surely outpacing you in efficiency and productivity.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.