There’s No Room for Error up in the Air

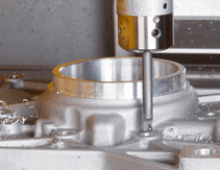

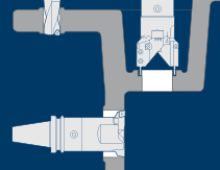

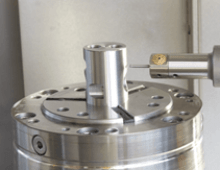

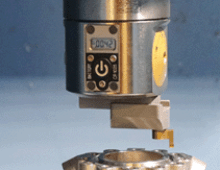

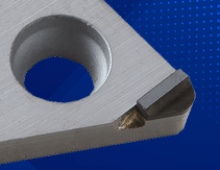

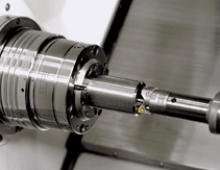

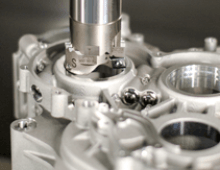

Jet engine manufacturers have found that even the most infinitesimal imperfection can produce catastrophic results; absolute precision is the name of the game in the aerospace industry. Manufacturers must meticulously inspect every hole to make sure it’s burr-free, each corner to make sure they blend seamlessly, and verify that machining hasn’t resulted in stress fractures. That’s where the rigidity and unique standard offering of a BIG Kaiser innovation can make life a little easier.

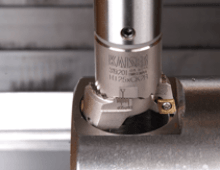

In the newest Aerospace Yearbook from Manufacturing Engineering, Our VP of Sales and Engineering, Jack Burley, examines our KAISER finish boring heads and how some recent flight-critical applications are gaining momentum in aerospace.

“Close enough” might as well be a four-letter word in aerospace. Eliminating just one operator variable, like having to convert metric tools to inch, increases the chances of a more repeatable and precise end result. Read here how KAISER’s “true inch” boring heads and other innovations make a few important variables things of the past in the industry that shapes the future.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.