This is a great article! I'd like to implement this approach. Do you back the boring head off the ID wall before retracting, or do you retract the boring head straight out? How much material do you leave for the boring head after the drill? Do you have more information on this application/technique? Thank you for the support!

A More Efficient Alternative to Rough Boring on a CNC Lathe

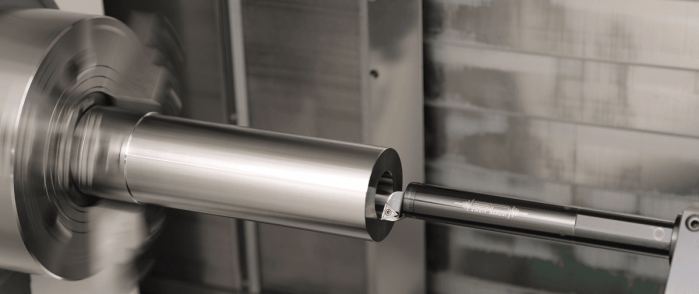

ID boring is a common and time-consuming operation on CNC lathes. The process typically starts with a drill that creates an opening for a more rugged roughing tool to come in and rough out the bore.

Indexable insert drills are nice, in that they can be used not only for their specified size but can also be offset to make a slightly smaller or larger hole; the tool itself doesn’t have adjustability, but you can shift the tailstock over itself to get a different final hole size. They can also be additionally offset and re-ran through the hole as a boring bar. That's not something that you can do when rotating on center as with a milling spindle. It’s one reason you rarely see a finish boring tool on a CNC lathe, unless it’s for off-axis work.

What’s more, as bores get longer, stepped and/or more numerous, important decisions come into play. For example, if the typical approach is to use one tool, send it in the bore, offset it, pull it out and repeat, you’re sacrificing much-needed rigidity at the back end of larger holes.

Spade- and replaceable-tip drills are also common holemaking solutions. However, they do not have the same flexibility as the indexable insert type drills and should not be used off center for additional boring type operations. Their lead angles are limiting and reaching them or deep into a hole, over and over, introduces risk while accelerating insert wear on only one cutting edge. Plus, drills don’t control chip wash very well, as their design pushes chips backward, often scarring up the hole’s finish.

These common issues are the reason we have developed ways to make some of our world-class boring tools—traditionally used on milling machines—just as effective on a CNC lathe.

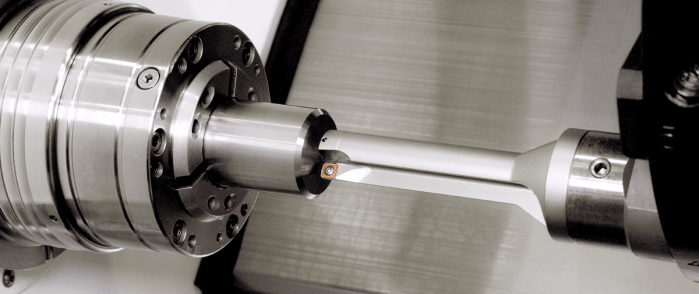

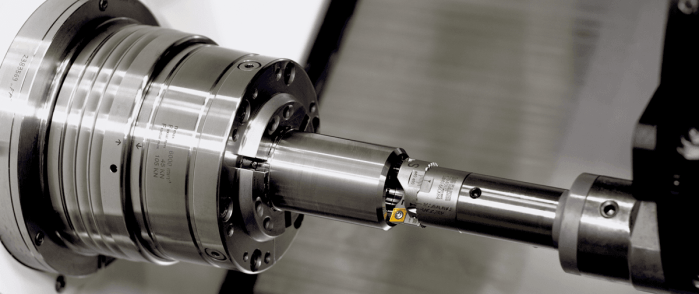

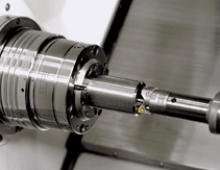

With a simple, short adaptor, our twin cutter rough boring heads can fit seamlessly into a lathe’s tooling package. The twin cutter series has a unique design feature allowing different roughing methods without the need to change components or use mechanical systems to adjust insert height.

The addition of a twin cutter boring head to a shop’s tooling arsenal opens the door to multiple holemaking options. Once thought of only as light-duty, semi-finishing tools, today’s high-performance twin cutter boring heads have proven they can deliver in holemaking operations.

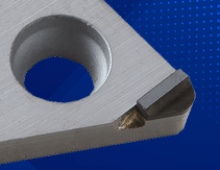

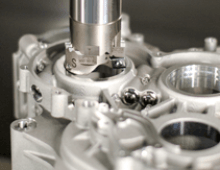

Eighty-degree diamond-shaped inserts provide two 90-degree cutting edges. This effectively doubles your feed rate instantly. If more cutting edges or speed would help and the negative six-degree lead angle is workable, you can switch to a square insert and have four effective cutting edges.

For larger holes, this assembly also offers the flexibility to use extensions to build a “custom” or more rigid setup, a superior alternative to reaching long, skinny tools deep into holes. What’s more, if vibration continues to be a nagging issue, the twin cutter makes it possible to employ the industry-leading Smart Damper boring bar, which maintains damping near the tool.

When boring holes on CNC lathe becomes too time-intensive, it’s time to reconsider your approach. Think creatively, invest in your own success. As they say, there’s more than one way to skin a cat, and twin cutters have proven to be one of those other ways that have proven to be even more effective than traditional approaches.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Comments

BIG DAISHOWA Inc.

Thu, 01/13/2022 - 10:43Hi Branden,

We're glad you found this article helpful. We've passed your information along to our engineers. They will be reaching out to you soon. Thanks!

Branden

Thu, 01/13/2022 - 10:34