Safer Boring Operations

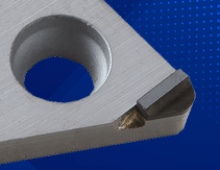

Dialing in a finishing job can be meticulous, with several measurements, adjustments and discussions taking place. That not only costs time, but those tool touches and interactions introduce some risk inside a shop. Our next boring innovation will help eliminate many of those repeated interactions and extra adjustments.

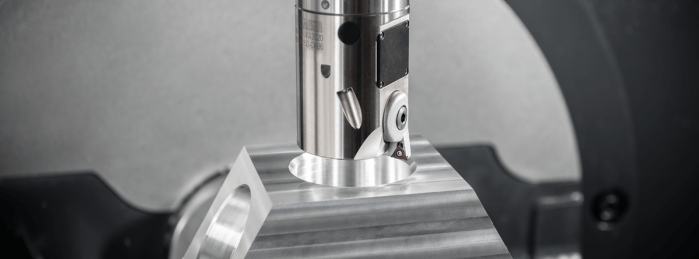

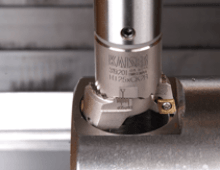

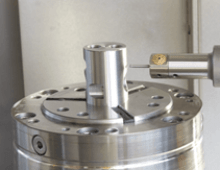

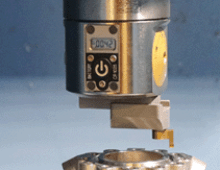

The EWA system is based on BIG KAISER's EWE digital fine boring heads and is being developed entirely by BIG KAISER. Expected to be released later this year, it’s an intelligent, fully automatic fine boring tool that doesn’t require manual adjustments. Motors inside the head provide unclamping and movement of the tool carrier based on input received through a wireless signal.

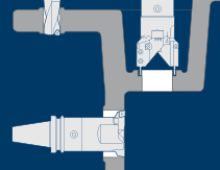

The EWA can be integrated in three primary configurations: tablet, PC or fully integrated:

Tablet Control

This represents the lowest level of integration. The fine boring head needs to be connected with the BIG KAISER boring app running on a tablet or smartphone. The boring head will automatically adjust according to the information the operator types into the BIG KAISER App.

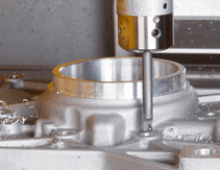

Once a bore is produced with the EWA, the operator can stop the boring cycle and measure the actual bore size with a precision bore gage or an in-process touch probe and put the correction into the tablet. Then the EWA will self-adjust to the correct value.

With the help of an integrated touch probe, the machining program will stop the boring cycle in the event of an out-of-tolerance bore and display an error message alerting the machine tool operator in order to make the required adjustment with the tablet.

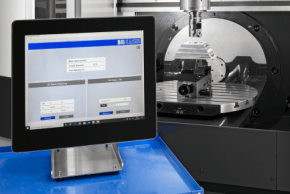

PC Control

For legacy machine tools, a PC interface between the machine tool and the EWA can be used to provide a fully automated, closed-loop control cycle where commands are sent from the machine tool to the EWA, automatically adjusting the tool in synchronization with the machining process.

In this solution, the integration with a legacy machine tool is done via a specific application running on an external industrial PC. This integration must be setup on site since much depends on the machine tool control type.

Fully integrated system

The full system can only be integrated on new machine tools. The EWA control software runs directly on the machine tool itself and requires no external control device. The interaction with the operator is done in the machine tool human machine interface in form of an App or a technology cycle.

As a reminder, the BIG KAISER Boring App is free and is much more than just the way to control our digital heads. It has operating instructions and extremely precise cutting data for all of our boring assemblies.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.