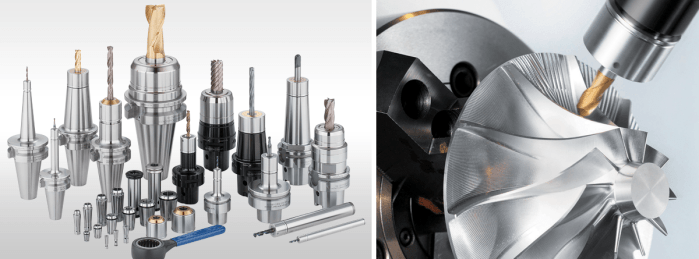

Asegurar una mínima excentricidad en sus portaherramientas tipo pinza

Cuando la alta precisión, la larga vida útil de la herramienta o la capacidad de alta velocidad son importantes, los portabrocas suelen ser la opción de sujeción preferida. Su sujeción tipo collar, generalmente fabricada con un material elástico como el acero para resortes, se aprieta mediante una tuerca de collet. Esto permite más puntos de contacto para la herramienta en comparación con otros portaherramientas.

También son versátiles porque el número de segmentos en un collet puede variar. Más segmentos significan mayor flexibilidad y un rango de sujeción más amplio, a costa de algo de concentricidad y estabilidad en collets más rígidos. Los collets son más útiles en trabajos repetitivos donde los requisitos de sujeción no varían significativamente.

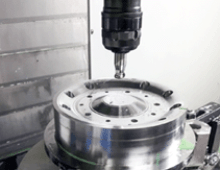

Dicho esto, los portabrocas no son inmunes al desalineamiento, o la inexactitud acumulada de una herramienta rotativa. El desalineamiento es inherente a cualquier sistema y no se puede compensar. Un desalineamiento menor significa un desgaste uniforme y una vida útil más larga de la herramienta, así como un mejor acabado.

Aquí hay más información que necesita saber sobre el desalineamiento en los portabrocas:

El tamaño de la herramienta importa

La relación longitud-diámetro y la masa afectan la fuerza al girar. Pero también es importante notar que dos herramientas de tamaños diferentes cortando con la misma cantidad de desalineamiento pueden producir resultados muy distintos. Cuanto mayor sea la herramienta, más resistente será al desalineamiento.

La tuerca correcta es importante

Una tuerca de collet con rodamientos en lugar de una tuerca sólida tradicional también ofrece un mejor control de la operación. Al apretar una tuerca sólida, las fuerzas de torsión pueden torcer el collet al aplicar los últimos grados de apriete con la llave. Una tuerca con rodamientos, aunque más cara, proporciona un apriete suave con baja fuerza de torsión sobre el collet. Esto permite una mayor fuerza de sujeción, mejor control del desalineamiento y menos desgaste del collet, prolongando su vida útil.

No pase por alto los tirantes (pullstuds)

A menudo considerados baratos y reemplazables, los tirantes no deben pasarse por alto cuando se trata de desalineamiento. Un tirante atornillado en un portaherramientas que no se alinea con la misma línea central que el cono y/o el sistema de retención generará fuerzas laterales sobre el sistema. Estos tirantes deben estar fabricados con metales resistentes y ajustarse con precisión para resistir deformaciones y posicionarse correctamente.

Comprenda el rango de sujeción

Los collets también son generalmente más adecuados para herramientas muy pequeñas en comparación con los portabrocas tipo mandíbula. Al elegir un collet con el rango de sujeción correcto, es importante recordar que todos los collets se colapsan sobre la herramienta seleccionada, no están diseñados para expandirse. Si un tamaño está escrito en el collet mismo, generalmente indica el diámetro máximo de herramienta que puede acomodarse.

Cómo diseñamos y mecanizamos nuestros portaherramientas para reducir el desalineamiento

- Materiales de precisión – Material, producción, tratamiento térmico... todo se selecciona para precisión, incluidos nuestros tirantes, que están fabricados en acero herramienta H13 premium endurecido completamente y todas las características son rectificadas con precisión.

- Alta concentricidad – cada uno de nuestros collets se inspecciona para garantizar un 100 % de concentricidad. Esto garantiza un desalineamiento dentro de 0.00004" en la punta.

- Opciones de diseño delgado, una variedad de interfaces que reducen la necesidad de extensiones para evitar interferencias, ideal para fabricación de moldes pequeños u otros cortes que requieren combinación de velocidad y alta precisión.

- Tuercas especializadas disponibles para un suministro de refrigerante más eficiente y protección de componentes pequeños del portaherramientas que pueden causar desalineamiento y otros problemas.

- Al aumentar la longitud de contacto del cono interno de los cuerpos de los portabrocas, se reduce el saliente indeseado del collet. Esta modificación del estándar mejora la rigidez y el apriete además de la precisión del desalineamiento.

- Un cono del collet más superficial y diseño de cuerpo grueso mejora la concentricidad para reducir vibraciones y desviaciones, logrando mejores acabados y mayor vida útil de la herramienta de corte.

Para conocer más sobre nuestra amplia oferta de portabrocas y estas y otras características altamente efectivas de los collets, haga clic aquí.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.

Añadir nuevo comentario