we are searching EWN boring head, model EWN 53-95CKB5

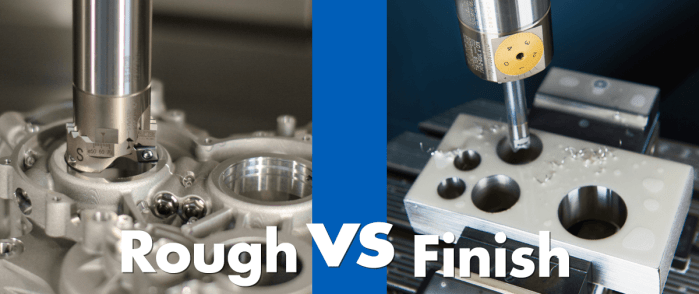

Rough Boring vs. Finish Boring

There’s more than one way to skin a cat, just as there’s more than one way to finish a hole. The most effective option will depend on the number of parts, acceptable cycle time and tolerance callouts. One of the most effective options is boring.

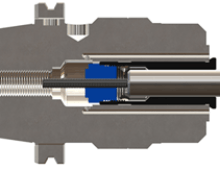

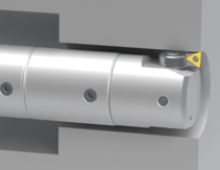

Boring, in its most basic sense, is internal turning. The first and foremost goal, like any other finishing process, is to enlarge a drilled hole to final diameter, which will usually have a precise tolerance. A capable boring tool will also clean up after the drill and produce a nice surface finish. Finish boring can be a delicate operation. After all, it takes only one oversized hole to scrap an entire part. So, oftentimes the drilled hole needs to be further prepped in order to improve the odds of success of the final cut-to-size. This is where the use of “rough” boring tool becomes a necessity.

The question is, when is it appropriate to use a rough boring tool versus a finish boring tool? Or should you use both?

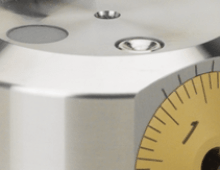

BIG KAISER rough boring tools are guaranteed to be accurate within +/- 0.004”, so at least with our tooling, anything tighter than that must use a finish boring head, no questions asked. That part is simple enough. If boring has already entered the conversation, you can probably assume that the tolerance will be much tighter than this anyway. So, it is rare that only a rough boring tool will be used.

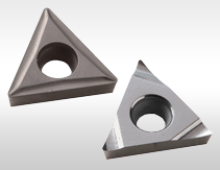

Next is material stock. The stock allowance of a finish boring tool will somewhat depend on the nose radius of the insert, but for conventional applications it will never really (and should never really) exceed 40 thou in diameter. In other words, unless you want to take multiple finish passes, any amount of stock greater than this amount will require the use of a rough boring tool.

With respect to the initial hole, this question also depends on whether the part is cast, the length-to-diameter ratio of the hole, and the required surface finish.

Casting processes dominate the metalworking process in many industries and will continue to dominate for the foreseeable future, despite advancements in additive manufacturing. They make possible the fabrication of otherwise difficult-to-machine parts, at relatively low cost and production time. But one thing casting is not known for is tight geometric tolerances.

Fresh out of the mold, a hole diameter can potentially be tens of thou away from a nominal value, which is why they’re typically cast well undersize. But equally as concerning (when it comes to boring) is the fact that the hole will also almost always be slightly curved or ovular to some degree. A rough boring tool is required to correct these issues before a finish boring tool can be used.

Another common cause of crooked holes is a wandering drill. This occurs when a drill “walks” off center very slightly when creating the initial hole, which mostly happens if the drill is slender, fed too hard or has a damaged tip. While the drilled hole might certainly appear straight to the naked eye, oftentimes using precise measuring equipment will reveal quite the opposite.

Why is a finish boring tool so sensitive to curved/out-of-round holes? Mainly because it’s one-insert effective, so it will only really experience radial force acting from one side. A finish boring tool is more likely to bend from radial cutting forces because it isn’t supported by an insert on both sides (as with a rough boring head) and taking off very little stock.

What this means is that feeding one of these tools into a crooked hole will encourage it to follow whatever path is set before it. The longer the hole, the easier it is for a boring tool to bend when cutting. This is also a problem encountered with reaming. So, it’s good practice to be extra cautious and make sure a long hole is already “true” before doing your finish pass. In contrast to a finisher, a rough boring tool does not really care about how straight the initial hole is, it will pretty much bore true regardless because most of the forces are axial.

Though it probably goes without saying, it also comes down to surface finish. Typically, a rough boring pass surface finish isn’t terrible, but some applications will specify a finish that isn’t practically attainable by a rough boring head. Obviously, a rough boring head isn’t as precise as a fine boring head, so this will show up in the surface finish, among other places. Surface finish only depends on feed and nose radius (by definition), but if it’s specifically called out in a bore, this is usually a good sign that you will want to use a single-insert finisher regardless of how you’re cutting.

| Hole Tolerance within +/-0.004" | Material Stock <0.040" on diameter | Long hole/ Cast part/ Nice Surface Finish | Required Tool(s) |

|---|---|---|---|

| Rough and Finish Head | |||

| Finishing Head | |||

| Rough and Finish Head | |||

| Roughing Head | |||

| Rough and Finish Head | |||

| Rough and Finish Head |

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Comments

BIG DAISHOWA Inc.

Fri, 03/21/2025 - 09:37Hi Cesar,

Thank you for your inquiry. We will be in touch with you soon.

Cesar Carrasco

Fri, 03/21/2025 - 08:27