Reducing L:D Ratio Provides Improvements

As discussed in past blog posts the L:D ratio of a tool assembly is calculated by using the length of the bar (or body) of a tool assembly and the diameter of the tool, not the workpiece bore diameter and depth.

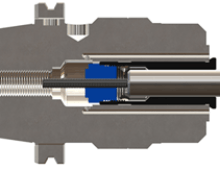

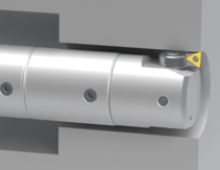

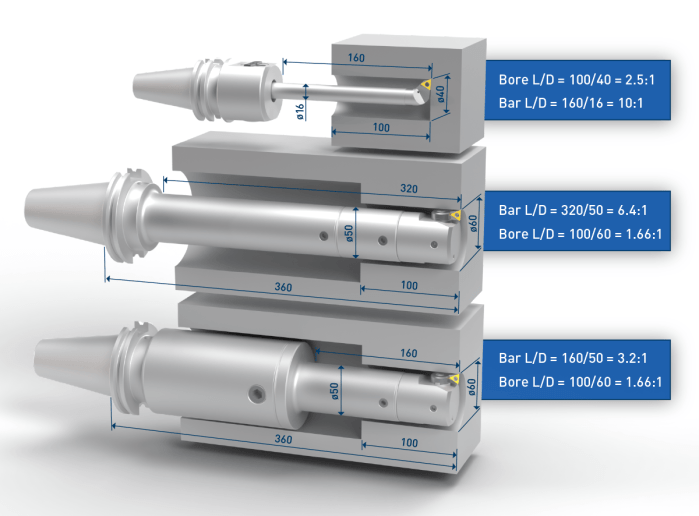

To expand on this concept, we see in the first configuration below the Ø16mm bar is sticking out 160mm which is a 10:1 although the bore is only a 2.5:1. In some applications this extra reach is needed to get around a fixture or a feature of the part. However, in those cases where it is not needed, decreasing the overhang by 55mm means the new L:D of 105:16 is 6.5:1. This alone would represent approximately 10x increase in cutting speed by increasing from 20mm/min vs. 200mm/min.

The use of modular reductions has also been found to be a good strategy to improve tool performance. Comparing the lower two assemblies below, the middle assembly uses the same connection size for the length of the tool, ignoring the larger access diameter, and results in a 6.4:1 ratio. When a shank with a larger connection size is used along with a modular reduction, the ratio is halved, and provides a 350% productivity improvement (14mm/min to 50mm/min).

In all cases, reducing the L:D ratio provides an improvement in speed which then provides longer tool life, better surface finish and size control of the bore.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment