Ground Chip-breakers vs. Molded Chip-breakers

Q: For boring operations, when would I use a ground chip-breaker vs. a molded chip-breaker? I am machining 4140 steel at 32Rc, and chip control is an issue.

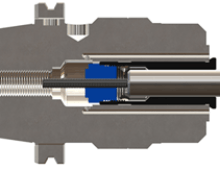

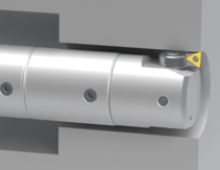

A: A ground chip-breaker is recommended for chip control issues. The high-positive rake angle will help to make shorter chips, and the chip groove orientation forces the chips forward to more easily evacuate them from the bore, especially when used with high-pressure coolant through the tool.

Ground chip-breaker inserts also provide lower cutting forces, so they are better suited for deep-boring or long-reach applications, and other situations where part or tool stability may not be optimal. They are also recommended for tight-tolerance applications where stock allowance is typically light for the final size pass.

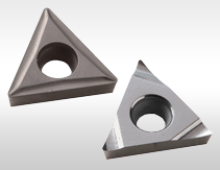

A molded chip breaker is recommended for stable applications in short-chipping materials. Because these situations don’t require a super-sharp edge for cutting the material, these inserts hold their edge longer for better tool life, and in most cases are less expensive.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.