Prolonging Tool Life of Deep Hole Drills by Using the Appropriate Pilot/Starter Drill

Selecting the appropriate pilot drill is critical to maximizing the performance and tool life of a succeeding deep hole or micro drill. The purpose of a pilot drill is to create a clean, consistent working surface for the succeeding drill to enter the workpiece.

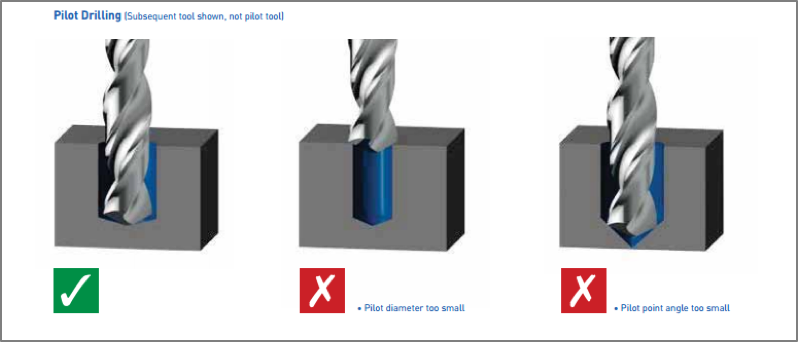

Important aspects such as diameter tolerance and point angle (Figure 1) are often overlooked leading to inconsistent, unacceptable results.

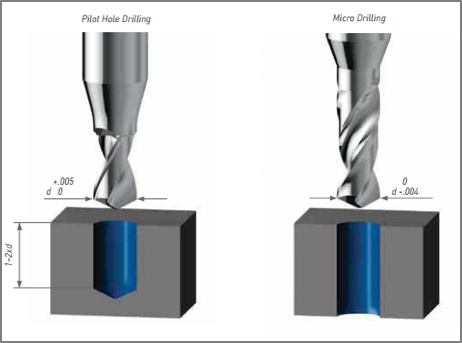

A pilot drill diameter should be slightly larger than the nominal diameter, whereas the succeeding drill diameter should be smaller. This is often accomplished using positive and negative tolerances respectively (Figure 2). Selecting the incorrect pilot drill diameter can lead to premature failure of the succeeding drill as it will enter the pilot hole using its margins rather than its center-cutting point.

It is also important for a pilot drill’s point angle to be equal to or larger than that of a succeeding drill. The purpose of a larger point angle is to guide the succeeding drill to the centerline while preventing its corners from colliding with the point angle left by the pilot drill. Using a pilot drill with a smaller point angle usually results in chipped corners on the more expensive deep hole drill after drilling 10-20% of the expected tool life.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment