Effects of Five-Axis Automated Machining on Tooling

How is automated five-axis machining boosting productivity? In a recently published article in Manufacturing Engineering, BIG KAISER’s workholding product manager, John Zaya, contributes to the conversations of the evolution of five-axis machines and how that affects tooling.

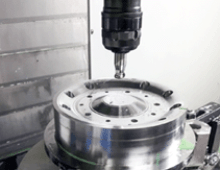

“The primary considerations when looking at tooling during the transition to a five-axis machine are reach, clearance, and balance,” says Zaya. “Toolholder balance, while important in any type of machine can become very critical in a five-axis machine that is being used to do ‘full five-axis work’. The cutting edge of the end mill must be consistently engaged with the material in order to prevent chatter and poor surface finish quality.”

Zaya also shares that holder types such as slim nose collet chucks, slim type hydraulic holders and slim type shrink-fit holders “are designed from the ground up to provide as much reach, clearance and balance.”

“Completely eliminating the holder is an option as more cutting tool manufacturers are providing integral taper cutting tools,” says Zaya. “Such tools interface directly with the machine spindle, thus eliminating many of the unwanted side effects of a holder with all the benefits of the machine spindle and its structural stability.”

In the full article, “Automated Five-Axis Machining Boosts Productivity,” Zaya shares more details on what to consider when it comes to tooling for a five-axis machine.

For any five-axis machining questions, please contact us online or via phone (224) 770-2999.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment