Nitro Manufacturing Fixes the Hole Problem

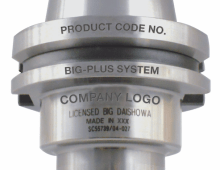

Nitro Manufacturing operator Nick Nowakowski is a big fan of the BIG Kaiser Mega Synchro Tapping Holder, model BBT30.

Nitro Manufacturing, LLC, a CNC milling shop in Hamburg, N.Y., is known for its specialty in industrial valves. They’ve developed a reputation for being able to promptly deliver extremely precise components with tight tolerances and lots of holes. But not long ago, they ran into a job that gave them fits.

Manufacturing News featured a recent article about the problem they encountered, and how they solved it with BIG Kaiser. Read the entire article here.

Here’s a quick snapshot:

This part required tapping titanium (6al-4v) with a 4-40 tap, a blind hole at .350” deep.

Job: 300 individual work pieces, 11 holes per component

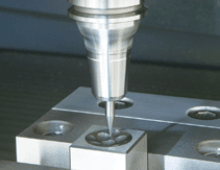

Operation: Tapping a blind hole at .350 inches deep

Material: Titanium (6al-4v) with a 4-40 tap

Problem: Snapping and jamming taps

Production rate prior to solution: 15 pieces, or 165 individual holes per tap prior to breakage or jam, at peak production

Tap cost per job prior to solution: $1,000 per job run

Solution: Mega Synchro Tapping Holder from BIG Daishowa

Production Rate after solution: 200 pieces, or 2,200 individual holes per tap

Tap cost per job with Mega Synchro: $25 per job run

How does it work? The Mega Synchro Tapping Holder has a unique feature that compensates for synchronization errors during rigid tapping. It improves thread quality and tool life by reducing thrust loads caused by synchronization errors by as much as 90 percent.

Click to see why the Mega Synchro Tapping Holder is such a capable solution for rigid tapping.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.