BIG Kaiser’s Wide World of Spindle Systems and Tool Holders

Because the BIG-PLUS® spindle system gets so much of our customers’ attention and interest, people often forget that BIG Kaiser offers an extensive line-up of other popular dual contact solutions, most notably HSK & BIG CAPTO. Across the board, dual contact tooling offers superior rigidity, accuracy and repeatability when compared to conventional systems. Each of the systems above has its fans and detractors, but overall, each does a great job for what it was intended to do. We’re certainly partial to the overall rigidity, precision and repeatability of BIG-PLUS®, but understand that there’s a place for all of these interfaces – which is why we offer them.

BIG Kaiser offers virtually all of our tool holding systems in all three major dual contact designs, such as our well-known collet chucks based off of the New Baby Collet, and our heavy duty milling chucks. But we didn’t stop there. In dual contact, we also offer ER collet chucks, hydraulic chucks, shrink fit holders, shell mill holders, end mill holders, modular adapters, turning tools for MTC’s, integral milling cutters, holders for rigid tapping and much more!

And since we are on the topic, when it comes to shrink fit, it’s indeed true that as a whole, they offer high clamping forces, low runout, and a small nose diameter to reduce clearance issues. BIG Kaiser manufactures our shrink fit holders to the highest standards with the highest quality materials. This enables us to slap our promise of “Higher Performance. Guaranteed.” on each that we sell.

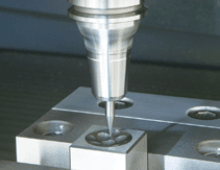

That being said, while shrink fit tools have carved out a definite place in metal cutting, our stance is that you pick the right holder for the job, no matter what it may be. For instance, when heavy duty milling with large diameter cutters, there are other options that can offer even better gripping force and at the same time, better runout than shrink fit. Our mechanical milling chucks such as the Mega Double Power and Hi-Power Milling Chucks offer higher gripping strengths for large cutters with minimal runout. For finish milling under ½”, BIG Kaiser’s Mega E Collet Chucks, for instance reduce the runout to no higher than .0001″ @ 4xd guaranteed, while a thick walled design and tapered body adds to the rigidity while not being too bulky for tighter areas. All of these options, used in the right application for what they were intended, will give you better results than shrink fit will. And they are more flexible thanks to long and slender interchangeable collets, and much easier to handle than shrink fit.

The bottom line is, to maximize productivity, it’s important to use the right tool for the job, and not to try and chose one end-all solution for your shop. That’s why BIG Kaiser offers not only the best, most precise, most accurate products available (even though we think these are pretty cool), but offers a complete complement of different tool holder styles for any application, and for any modern machine tool spindle.

For BIG-PLUS® tooling, click here.

For HSK tooling, click here.

For BIG CAPTO tooling, click here.

View our collection of catalogs spanning our entire offering of products here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.