Conventional Tool Holders are Not All Created Equal

Every millimeter counts in metalworking. That’s why it’s important to think twice when selecting conventional tool holders like shell mill, end mill and shrink fit holders. If you’ve ever used tooling from BIG KAISER to help solve a cutting or production challenge, you understand the quality, the engineering and, of course, the “Higher Performance. Guaranteed.” we offer. Our conventional holders are no different.

Since they are only offered in dual contact interfaces – these superior levels of rigidity reduce deflection and allow us to offer extended gauge lengths off-the-shelf—shell mill holders up to 12” for example—that will have excellent performance like that of a stubby gauge length. Dual contact interfaces also provide repeatable positional accuracy after tool changes, and eliminate any Z-axis movement when drilling with our shrink fit holders.

Another hi-light to our conventional tool holders program is the variety of incremental gauge lengths, allowing you to match tooling to the exact parameters of each cut without having to get creative or take unnecessary risk. No one wants to use a tool holder longer than necessary.

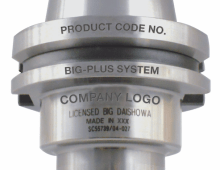

Always in search of ways to make life easier on the end user, we also offer inch sizes for traditionally all-metric offerings like BBT and HSK as well as metric sizes for some traditionally all-inch CAT tools. By the way, all of our inch tools are made in the U.S., and metric by our parent company BIG Daishowa.

One of the exciting newer additions to our shell mill holder lineup is the BIG-PLUS® high-rigidity BCV40/50 holder. Compatible with the new 2009 revision of the ASME B5.50 (CAT) standard, the elimination of the safe zone past the v-groove greatly improves rigidity for higher performance milling applications*. Learn more about this new addition in our Fall 2015 Supplemental catalog.

NEW!!! High Rigidity Type made to ASME B5.50-2009 CAT Standard (no safe zone)

BIG KAISER conventional tool holders are available in the following interfaces and sizes.

Shell Mill Holders

InterfaceDiameter (in)Diameter (mm)

BCV40/50.750 – 2.50022 – 60

BBT30/40.750 – 1.50016 – 32

HSK-A40/50/63/100/1251.000 – 1.50016 – 50.8

C5/6/81.000 – 1.50016 – 38.1

CKB4-CKB7.500 – 2.000N/A

End Mill Holders

InterfaceDiameter (in)Diameter (mm)

BCV40/50.375 – 2.500N/A

BBT30/40.250 – 1.2506 – 32

HSK-A63/100/125.750 – 2.00012 – 50

C6N/A16 – 32

CKB4-CKB7.1875 – 2.000 6 – 40

Shrink Fit Holders

InterfaceDiameter (in)Diameter (mm)

BCV40/50.250 – 1.2508 – 12

BBT30/40.250 – 1.0004 – 20

HSK-A40/50/63/100N/A4 – 20

C6N/A6 – 20

For specs, detailed performance metrics and application tips for using BIG KAISER’s broad offering of conventional toolholders, view the full catalog now.

Besides what was mentioned above of how we set ourselves apart – we can also deliver most of these tools overnight if needed. Feel free to check out our impressive stock levels and see for yourself. Not too sure there are many other suppliers than can get you a BBT40 Ø.500” end mill holder next day! Heck, at the time this was written, we could have shipped you 29 of them!

*Keep in mind, not all machining centers are capable of accepting the new 2009 revision and caution should be taken before installing these high rigidity tool holders. Always consult your machine tool manual or the machine tool builder for information about tool change requirements.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.