Your Ultimate Guide to Reduce Vibration in Machining

-

Machining vibration disrupts operations by causing oscillations between the cutting tool and workpiece, leading to poor surface finishes, reduced tool life, and slower speeds and feeds.

-

Common culprits of machine vibration include machine instabilities, improper spindle or tooling setups, and inadequate workpiece fixturing.

-

Advanced technologies like vibration-damping materials and BIG-PLUS dual-contact spindle systems help mitigate vibration issues.

As all machinists know, machining vibration is the sworn enemy of high-quality and efficient metalworking operations. The effects of vibration impede speeds and feeds, reduce tool life and wreak havoc on the part finishes. But solving for vibration can be tricky as the culprits are widespread and often interlinked.

CNC Machine Vibration 101: The Basics

Seasoned machinists understand the basics of CNC machine vibration, but for some, a vibration 101 refresher may be helpful. Before solving vibration issues, we have to understand what it is and why it’s important to reduce it.

What is Machining Vibration?

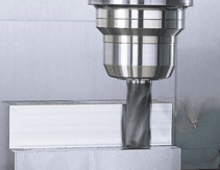

Machining vibration is a mechanical phenomenon involving oscillation that occurs around a central point. In machining processes like milling, turning and drilling, these vibrations manifest as periodic movements between the cutting tool and workpiece, disrupting the intended machining operation. The oscillations can be either resonant, occurring when the system vibrates at its natural frequency, or non-resonant, typically caused by factors like uneven tool wear or mechanical issues.

What are the Impacts of Machine Vibration?

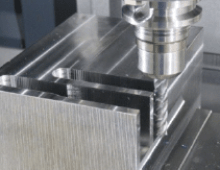

The impacts of machining vibration are significant and multifaceted. At the most immediate level, vibration degrades surface finish quality, creating undesirable wavy patterns or regular marks on machined parts. In applications that require tight tolerances and mirror-like finishes, this can lead to the expensive problem of high scrap rates and blown timelines. But even in lower-precision applications, vibration can significantly impact a shop’s bottom line. More on that later.

Most Common Causes of Machine Vibration

Machine Issues

The machine tool itself can be the cause of vibration—either because of instabilities within construction or the cutting process—fast directional changes and quick stops and starts, for example. Fortunately, machine tool builders are working on technologies that can help minimize naturally occurring machine vibrations. For example, many newer CNC machines feature technologies like real-time vibration sensors that work with adaptive control software to continuously monitor and adjust machining parameters to minimize vibration. The physical design of machines also evolved—with many machine tool manufacturers using materials that have natural vibration-damping qualities and designing machines for enhanced structural rigidity.

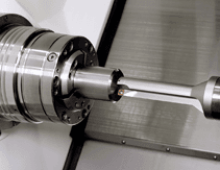

Spindle and Tooling

Anywhere metal meets metal in your machining setup is a chance for vibration to occur. The more secure and rigid the contact, the less risk of vibration. Our BIG-PLUS Dual-Contact Spindle System is designed with this in mind. Many machine tool builders depend on simultaneous taper and flange contact for improved rigidity and vibration reduction, but not all dual-contact systems are created equally. BIG-PLUS is THE ONLY true dual contact system for 7:24 taper systems—more on that later.

Another important tooling tip is to use the largest possible diameter and the minimum possible length in your tooling assembly to minimize vibration.

Workpiece and fixturing

Subpar workpiece placement and fixturing can significantly amplify vibration issues during machining operations. When fixturing is inadequate or improperly designed, it creates a weak foundation that allows the natural forces of cutting to induce unwanted movement and oscillation. This is particularly critical when working with thin-walled parts or components with minimal support structures. To maintain stability, the workpiece should be supported as close to the machine table as possible, with cutting forces directed toward the most rigid areas of both the fixture and machine structure. Modern solutions, such as mineral-cast workholding systems, offer superior vibration dampening compared to traditional materials.

Effects of Vibration on Machining Operations

As mentioned earlier, vibration isn’t just the enemy of perfect finishes. It can have detrimental effects even in applications that don’t require ultra-tight tolerances. Let’s explore some of the ways vibration can affect your operations.

Machining Efficiency

High levels of vibration will often require operators to reduce speeds and feeds, ultimately slowing down operations. In an industry where time is money, this could represent a huge opportunity cost.

Part Quality and Scrapped Parts

In high-precision applications like aerospace, medical and automotive, vibration is especially risky. Particularly when working with expensive materials and large workpieces, one scrapped part could represent thousands of dollars in lost revenue.

Tool Wear and Breakage

Vibration has a substantial negative effect on tool life—causing accelerated and unpredictable wear patterns on cutting edges. In fact, it’s a proven fact: One study revealed that “the cutting forces and vibrations generated in machining adversely affect the tool life, workpiece, quality and cost. It mainly accelerates the tool wear, which decreases the surface quality and functional life of a cutting tool.” In extreme cases, vibration can cause tool breakage, which puts the part, machine and operator at risk.

Machine Health

Beyond the tooling, machining vibration poses risks to your machines—at the least, stressing machine components and causing premature wear; at the worst, you could face downtime and catastrophic machine failure. Finally, the unpredictable nature of vibration-induced wear makes it difficult to implement reliable predictive maintenance schedules, further complicating production planning and cost management.

Techniques for Reducing and Preventing Machining Vibration

As mentioned, machine design and workpiece setup can be optimized to minimize vibrations. But the elements most in your control are related to tooling and cutting techniques.

Use Vibration Damping Tech

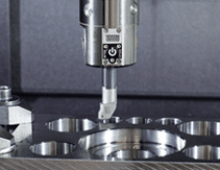

For longer tooling assemblies or complex cutting applications prone to vibration, operators may need a little extra help. That’s where modular vibration damping components come in. The BIG DAISHOWA Smart Damper products, for example, are designed for rough and finish boring or milling applications that call for additional protection against vibration.

With Smart Damper, a heavyweight, strengthened damping mechanism is integrated into the tool holder and functions as both a dynamic counter and friction damper. It instantaneously absorbs vibration and eliminates chatter helping to achieve higher machining accuracy, better surface finishes and increased metal removal rates for higher productivity at critical machining depths. It’s also designed with the capability of supplying coolant through the body directly to the cutting edge.

Vibration-damping workholding solutions are another option. BIG DAISHOWA has a variety of workholding solutions all designed for ultimate stability and flexibility. For example, our multi-axis workholding products are ideal for 5-axis machining with multiple-part transfers because they locate and stabilize the workpieces without obstructing access to the top and sides of the part. Plus, they let operators easily flip the orientation of a clamped workpiece to speed up operations.

Pay Attention to Tool Assemblies

Longer tooling assemblies are sometimes required for complex or large parts. But as mentioned, the longer the length-to-diameter ratio, the higher the risk of vibration. This is where it pays to use the highest-quality modular tooling. Modular tooling from BIG DAISHOWA is designed to exacting standards to ensure ultimate rigidity, clamping and tool life. But more than just flexibility and quality design, our modular tooling is backed by application expertise. We often advise customers on tricky applications—to help improve productivity while decreasing the inherent risk of vibration that comes with longer modular tooling assemblies.

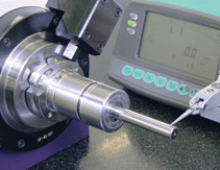

Get Better Rigidity with Spindle and Tool Holders

As mentioned, dual-contact spindle and tool holding systems are the way to go to reduce vibration and improve accuracy. While many manufacturers claim to offer dual contact, BIG DAISHOWA is the only true dual-contact tool holding licensed for BIG-PLUS spindles. Others simply don’t have the gages and dimensions to reproduce true dual contact between the tool holder and spindle.

Choose the Right Technique and Programming

For vibration-prone operations, there is a sweet spot for feeds, speeds and cutting depth. But there are also specific programming techniques for vibration reduction. Trochoidal milling for example, can be good for milling operations because it helps reduce the amount of sudden starting and stopping and directional changes that can cause vibration. Other programming tricks that can combat vibration include:

- CAM software can help maintain constant chip thickness which helps reduce vibration

- Circular interpolation with a smaller tool in the corners of a workpiece can help maintain a machine’s natural frequency

The latest machine and tooling technology can go a long way toward vibration-free machining. Talk to a BIG DAISHOWA expert today for application-specific tools to reduce vibration, improve productivity and boost your bottom line.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.