Why Modern Shops Need Tool Presetters

Machine shops of all shapes and sizes are facing more pressure than ever. Whether it’s just-in-time demands of customers or a competitor's technological edge, the accelerated change over the last two or three decades forces companies to find their advantage wherever they can to compete. A tool presetter is a single piece of equipment that can provide immediate efficiencies and pay for itself relatively quickly. While its primary purpose has traditionally been tool setup, presetters serve as both important tools and information hubs on the floor as technology advances.

What is a tool presetter?

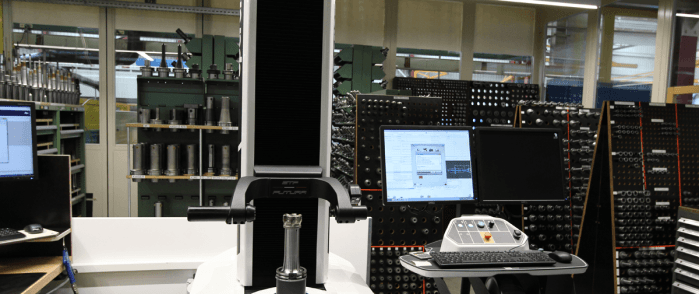

A tool presetter is primarily a measuring system used to verify tool geometries before putting them into a machine's spindle. They can be benchtop or standalone with touch- or vision-based measurement. It's a way to measure things like offsets and diameters, among other things. This essentially eliminates this work at the machine tool so that spindles can remain spinning while it’s done at the presetter.

Just how impactful can this kind of change be to a shop? It’s easy to find out. This Presetter Cost Payback Calculator will help you estimate how much money you'll save moving some setup time away from the device based on the machines in your shop.

One of our favorite examples of how these efficiencies come to life in the shop is switching from positive to negative tool offsets. Made more manageable by a presetter, this simple change allows for more standardization on the shop floor, reduces the burden on operators, increases setup speed and dramatically reduces the chances of human error. All of which saves time and realizes return.

Case study: Oil and gas supplier reduces setup time 60 percent

Gearench produces more than 40 separate product lines exclusively for the oil industry used in exploration, drilling,

production, refining and completion. With the help of a MAGIS 400 tool presetter, machine downtime was eliminated, leading to an annual savings of more than $81,000.

“The MAGIS has become a valuable asset to our production process and will continue to be utilized as a major engineering tool in our machining process costs,” said Zack Fehler, manufacturing engineer at Gearench. “The Speroni tool presetter has allowed us to maintain our supreme level of quality while simultaneously cutting costs.”

Other efficiencies gained with a tool presetter

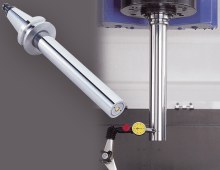

TMS Sales Specialist Patrick Cratty, and host of the popular YouTube channel NYC CNC, John Saunders, discuss how presetters work in more detail. They describe how presetters go beyond production efficiency and make proactively spotting runout and tool wear much easier. Beyond just measurement, inspecting tools with a presetter offers great value too.

Runout decreases tool life and part accuracy. Compromised part accuracy could lead to scrapped or reworked parts. How will you know the impact runout has if you don’t check it? Don’t waste thousands of dollars buying tools that could have been adjusted, indexed or reground instead.

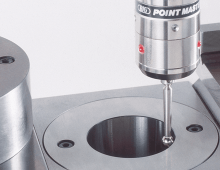

Presetters are useful if you work with unique tool geometries. Step tools, for example, may have several critical dimensions that can easily be checked on a vision-based tool presetter. Lathe tools may also have geometries that require verification. All can be easily measured and verified on a vision-based tool presetter. Vision-based presetters also include a front light for visually inspecting the cutting edge for wear, fractures and surface finish on reground tools.

Taking advantage of data with a presetter

Data is a powerful business tool. As technology moves along, it is becoming easier to collect, organize and use. Companies that can use their data for optimization and planning have a clear advantage over their competition. Presetters are a great way to start and serve as a floor-up gateway to Industry 4.0 without dramatic disruption.

“Take a moment to think about if you had data on a tool’s dimensions, usage, and if a certain assembly was running out,” says Doug Sumner, our TMS technical specialist. “Now, imagine how you could use that information to expedite setup time in the tool crib, reduce scrap and waste, even track what’s happening on the floor. That’s the kind of information a tool presetter helps you capture and leverage.”

Integrating the systems to make the most of this data is done quickly with new software and sensing technologies. For example, our presetter software, Edge Pro, can communicate with other software to verify length, diameter, create a G-Code and post-process with exact tooling values.

Taking things a step further, using a scalable software structure and local workstations, a tool management system like Intelligo links an entire tool library, active or inactive, with CAM tool-crib management, purchasing, scheduling and ERP software, giving users access to a rich set of features that ensure a greater and more seamless flow of information throughout the shop. This is how successful shops get the most out of every tool throughout their lifetime in the shop.

Using RFID sensors, QR or barcodes on the tools, installed or created at a presetter, systems like Intelligo can recognize components such as cutting edges, tool assembly, carts and baskets through wireless networks as they travel the shop. RFID is beneficial because a tool assembly’s data can remain with the tool on an embedded chip. It’s probably the most accurate means of transferring tool data, as it eliminates room for error and allows you to track the life, or expected obsolescence, of a cutting edge, holder or assembly—no more wandering the floor.

Case study: Shop digitally maps, organizes and verifies 14,500 tools

Bruderer AG, a sophisticated stamping machine manufacturer, had an inventory of 7,500 tooling components that they applied in 14,500 different configurations.

The company has synched its presetters with both its existing TDM system and its machine controls. This allowed for automatic verification of tool assemblies before reaching the spindle and proper workpiece/process pairing with the tooling once situated in the machine tool. This has resulted in reduced human error, 30 percent faster setups and protection from collisions.

Head of production, Remo Ackermann, put it this way, “A perfect fleet of machines with slow tool measurement get you nowhere. The new Speroni measuring machines have strengthened our workflows, and the return on investment is very fast indeed.”

Finding the right tool presetter

You don’t have to do it alone. We’re happy to work with you to right-size your presenter's array and make sure it’s equipped for everything you need. While you’ll surely want to choose something that makes an immediate impact, for the best long-term return, consider how you may want to use it in the future, with new or different customers.

Get started comparing different kinds of presetters with our Presetter Selection Guide using your shop's criteria, this helpful infographic or explore our latest Tool Measuring Systems catalog.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.