Don’t Cheat When Tightening Tool Holders

Cheater bars are appropriately named, especially when it comes to tightening tool holders. We see the common pipes that are often added to the end of wrenches to achieve more torque in customers’ shops all the time. And while these makeshift wrenches may make tightening or loosening holders easier, the damage they can cause is often overlooked.

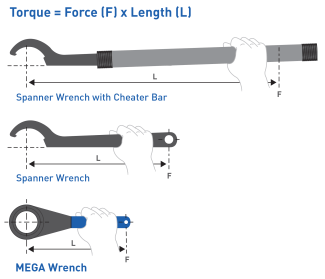

Considering the wear and tear an operator can deal with tightening with cheap wrenches, it’s understandable why it’s tempting to grab a cheater bar. For example, if a milling chuck is recommended to be tightened using 50 ft.-lbs. of torque force, you’d need to apply 50 lbs. using a one-foot wrench; if the wrench was only six inches long, you would need to apply a whopping 100 lbs.; where as if the wrench was two feet long (as in the use of a cheater bar), you only need 25 pounds of force.

The problem is that with a cheater bar, torque force is amplified so much, and so inexactly, that collet nuts are often over-tightened again and again. This can be costly in a lot of ways. It's a common misconception that tighter is better—tool holder torque limits exist for good reason. Any tighter than the suggested torque limit and you will induce internal stresses in the tool and holder, decreasing tool life. In some cases, over-clamping induces runout too.

One way of lessening the strain and cost of tightening holders—and reliance on cheater bars—involves the design of the nut itself. As a solid nut is tightened, torque forces slide its face along the top of the collet, twisting and wearing the collet with the last few degrees of a wrench pull. In bearing nuts, on the other hand, the collet is free to rotate without the nut, reducing wear caused by the sliding motion. This extra “give” also reduces the torque required to tighten them and resulting wear.

One way of lessening the strain and cost of tightening holders—and reliance on cheater bars—involves the design of the nut itself. As a solid nut is tightened, torque forces slide its face along the top of the collet, twisting and wearing the collet with the last few degrees of a wrench pull. In bearing nuts, on the other hand, the collet is free to rotate without the nut, reducing wear caused by the sliding motion. This extra “give” also reduces the torque required to tighten them and resulting wear.

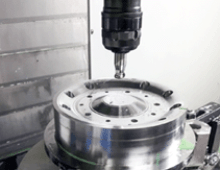

The collet shown above has severe wear as a result of high-torque clamping. This cannot be expected to hold cutting tools properly. BIG KAISER MEGA collets will still look brand new, even after several hundred clamping cycles.

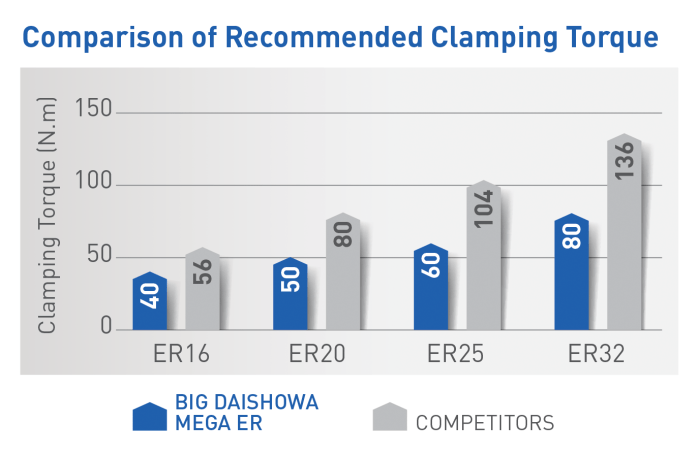

To show how different the clamping is between different style nuts, we compared the recommended clamping torques of our bearing-style milling chuck, the MEGA ER Grip, with competitors’ solid anti-friction nuts. In the end, we found that the bearing-style MEGA ER requires 30%-40% less clamping torque, while still achieving higher gripping force—the best of both worlds.

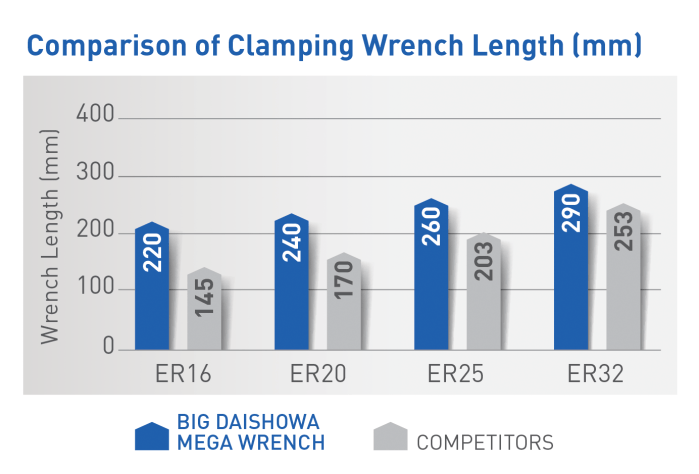

Another way to reduce the chances of wearing out holders with overtightening is with the tool itself. We’ve touched on why cheater bars aren’t a good idea and how the right nut can make tightening easier, but there are wrenches made specifically for safely and accurately tightening holders. As we described in the example above, a longer wrench does make things easier. Our MEGA Wrench, for example, is 15-35% longer than competitor models and has an ergonomic rubber grip to make tool room attendants’ and operators’ jobs easier.

When the right nut design and proper tightening tools come together, things are even easier. The nut design also allows for even 360-degree clamping. Cheater bars may make life easier, but the perks are only short term. The right holder and/or the right tightening tool can pay off big in holder costs in the long run.

Using torque wrenches is our first choice and we offer them for all our collet holders. Learn more about our MEGA series collet chucks here and our MEGA wrenches here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.