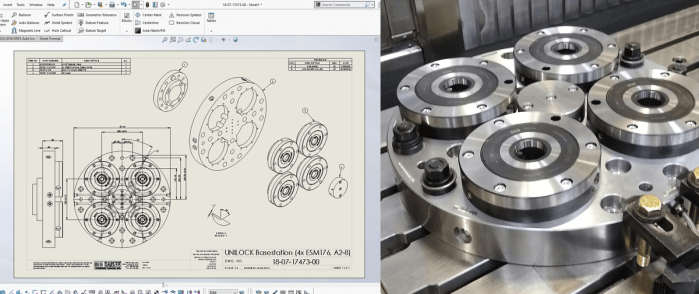

Move Beyond Standard Tooling

When defining tooling requirements for a new project, oftentimes standard tooling is all that is needed. Other times, custom or special tooling is required. In his latest article, “Move Beyond Standard Tooling,” for Fabricating & Metalworking, Product Manager John Zaya explores the role each has in today’s manufacturing environment.

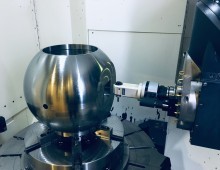

- A standard product selected from a catalog is often the first choice for many applications. Generally mass produced to keep costs down, the flexibility that standard products offer allows them to be used in multiple applications.

- Many manufacturers use special and custom interchangeably, however, for us a custom tool is based on a standard item with as little as one feature altered from the standard, such as length in order to gain more reach; a body diameter smaller than standard to gain more access; or an item that is no longer stocked. There is always the customer who falls in love with a product and will buy it even after it is no longer cataloged. We put these items in the custom category. We also consider custom tools to be those used in machining centers that are no longer standard.

- The time needed to work up an initial concept and quote is a major factor in classifying an item as special. Special items are game changers that give customers a competitive edge when it comes to making parts they sell or incorporate into final products. Time varies based on the number of options and complexity of the design, ranging from two to three hours up to 15 hours to generate the full and final manufacturing prints.

For more information on moving beyond standard tooling, click here to read the full article.

Categories

Tags:

Tooling Solutions

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.