Where Will the Digitalization of Tooling Take You?

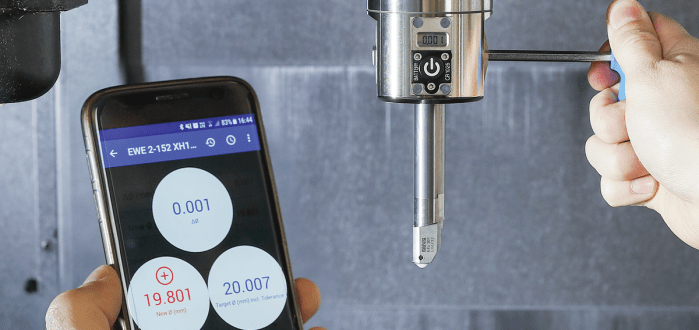

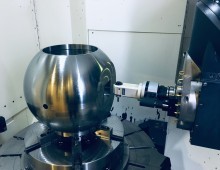

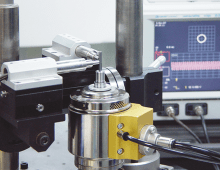

Exciting improvements in automation are already on their way—higher productivity, increased safety, greater throughput and less scrap. Breakthrough manufacturing processes include remote monitoring and automation, cloud-connected machine controls and robotics. More so, tool digitalization provides opportunities for production improvements, like our EWE digital fine boring tool. It displays the actual diameter of a tool, makes adjustments much simpler and faster, and reduces human error.

BIG KAISER Research and Development Engineer Nick Jew breaks down the process of digitalization in a recent Fabricating & Metalworking magazine article, “Next Steps in the Digitalization of Tooling and Its Impact on Operators.” He explains tools like the EWE are only the beginning in digitalization. Next is closing the automation loop. The EWA fine boring head is currently in development—its remote Bluetooth commands will eliminate wasted time and risk that comes with an operator making manual adjustments. Lights-out boring becomes a real possibility with such innovations, adding versatility and speed to boring operations.

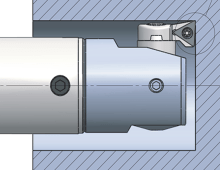

Direct communication with machine control will naturally follow the adoption of these improved operations, followed by the integration of sensors into the tools and/or fixtures. This will have impressive effects on diagnostics and error prevention, like revealing imbalances and validation of speed within the proper range. These sensors can recognize damaged or worn cutting edges, and record overall cutting quality.

Jew recognizes that changes in the status-quo will usher in a new era of tool digitalization. This, of course, begs the question of what will happen to the operators? It’s easy to assume that they will lose their jobs to machines. This is not the case—these tools will make their current jobs easier and safer. They’ll be able to do more with the mobile devices they use every day; they’ll be freed to perform other tasks like preparing new workpieces or tool setups.

Improvements to digital tools are here to stay, and there’s more to look forward to down the road. Operators will learn how to use the tools, controls and sensors effectively, making their lives easier and jobs more enjoyable in the long run.

Read the full article now for more information on digital tools and the changes they bring to the automation industry.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.