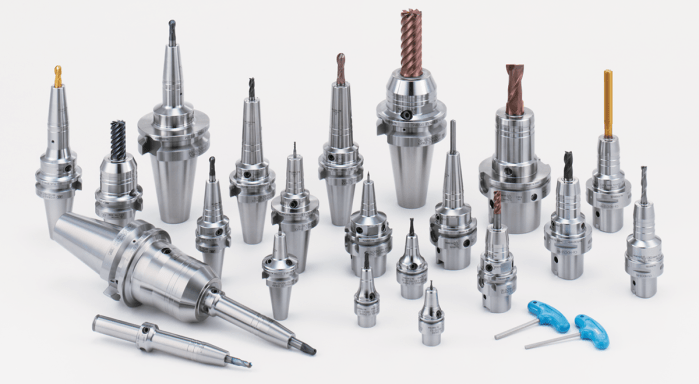

Tips for Selecting a Long-reach Tool Holder

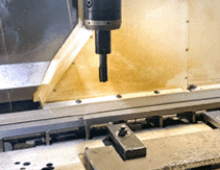

Deep pockets in mold cavities can be difficult to machine. Tool holder length-to-diameter ratios are stretched to the max and cutting forces are high. Without the right tool holder, these conditions create the perfect storm for chatter, poor tool life and failing quality control molds. To avoid such problems, consider a wide range of factors when selecting a long-reach tool holder.

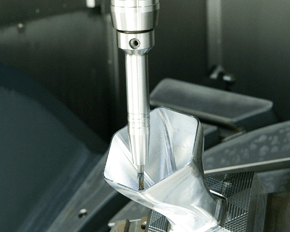

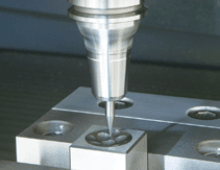

- Reach and access. Compared to collet chucks and shrink-fit holders, hydraulic chucks have a smaller nose diameter relative to the tools they hold. This is critical, as these holders allow a further reach into the mold without interference, which is becoming more important with the increase of five-axis mold machining and its longer reach requirements.

- Vibration damping. Hydraulic chucks lessen vibration and provide better surface finishes than competing methods. Potential out-of-balance issues due to a hydraulic holder’s one-sided set screw design are a worry of the past. A good-quality hydraulic chuck runs every bit as true as a shrink-fit holder, without the hassle and expense.

- Holding power. One area where shrink-fit has the upper hand is speed. For example, a hydraulic chuck may be rated to 35,000 rpm. Above that speed, hydraulic fluid is pulled away from the holder’s internal gripping gland, causing loss of clamping force. But when used within its recommended operating range, a hydraulic tool holder offers superior runout and repeatability. On average, a good shrink-fit holder has about 0.0003-inch runout, while a hydraulic chuck offers 0.0001 inch or better.

- Gripping strength. For optimal gripping power, the use of cutting tools with shanks ground to H6 tolerance or better is recommended, since gripping force drops off exponentially as shank diameters decrease. Consider a typical ½-inch-diameter end mill. With a shank measuring exactly 0.500 inch, both shrink-fit and hydraulic holders provide 100% available gripping strength. But with shank diameters in the lower range, below 0.0005 inch, gripping force drops by roughly 60% while hydraulic loses only around 20%.

- Jet coolant capability. While hydraulic tool holders are generally best for finishing these long-reach, small-cavity applications, jet coolant makes them even more effective. By introducing coolant through the end of the tool holder, angled directly to the cutting tool tip, the tight areas—where it’s needed most—are cleared of chips, greatly improving surface finish and tool life.

Maintaining Performance

Tool holders should be cleaned regularly in order to ensure peak performance. Using a certified test bar for regular checks of a tool holder’s gripping force is recommended, as this gripping force tends to drop off when tool holders approach end of life. Don’t forget about the machine tool as well. The spindle drawbar’s clamping capability should be routinely verified to maximize its capabilities.

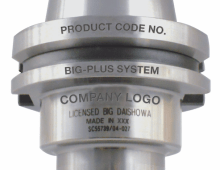

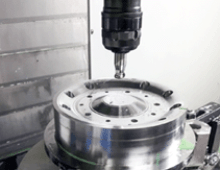

Balance is critical in long-reach milling applications too. For the best results, always balance tool holders as a complete assembly. Many tooling providers pre-balance their holders at the factory, but this is often inadequate, especially for long-reach applications. CAT and BT-style holders should be balanced with the retention knob and cutting tool in place, and HSK holders with the internal coolant tube installed.

Hydraulic tool holders are precise devices, so proper care is essential to keep them functioning at their best. Keep in mind that operators should never engage the hydraulic clamp unless there’s a cutter in place and never use Weldon-shank tools because both will damage the hydraulic mechanism.

View our hydraulic tool holders to see how they can help in your application.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.