Top 5 Boring Tool Tips from BIG KAISER Experts

Boring operations can present several challenges, and there are a lot of equipment options available to help tackle them. Matching the right tools and strategies to your application—roughing to finishing, prototyping to production—goes a long way. Here, our engineers, who spend a lot of their time thinking about solutions to customers’ boring difficulties, share some of their most valuable advice.

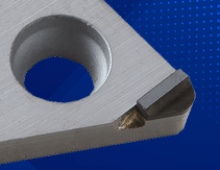

An alternate approach to lead angles

Conventional wisdom says to use the longest lead angle possible, thinning the chip because it allows you to increase speeds and feeds. We take a different approach. We prefer lead angles closer to 90 degrees because they apply the least amount of radial pressure against the tool. This is much more effective to combat the chatter and vibration that compromise part productivity and tool life. You can learn more about boring with the right angle, here.

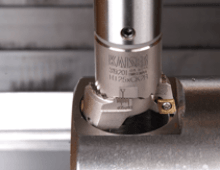

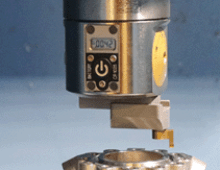

Digital boring heads are more than just a convenience

Sure, digital boring heads make life a lot easier on operators, but they also enhance performance. The heads give a zero setting that can always be a new starting point for a new insert. Each adjustment is stored in the head to give a total life for each insert, so every operator knows where the tool is. Read how LORD Corp. took advantage, to eliminate expensive scrap in low-machinable material.

The right steps to set up the cycle

It’s important to get as much right as possible before you put the head to the part. This means keeping the projection ratio of the boring bar within 4:1 (L:D)—or as short as possible—and selecting a preliminary speed at which you can obtain safe cutting operations without overload or vibrations. That said, never change feed and speed in the same step; things can get confusing. You can find more optimization advice here.

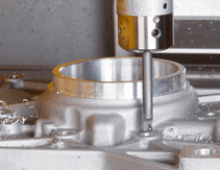

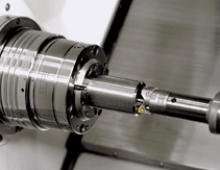

Avoiding vibration

The effects of vibration impede speeds and feeds, reduces tool life and wreaks havoc on a part’s finish. Vibration can almost always be attributed abrupt changes in direction, instability in part processing or inconsistent forces during operations. Effective ways to combat vibration include using the largest possible diameter and minimum possible length and/or licensed dual-contact tooling. Learn more about these approaches to vibration and others here.

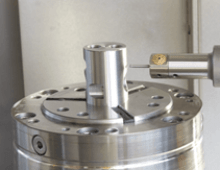

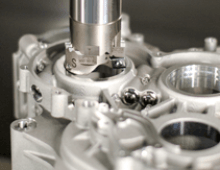

Reconsider helical interpolation

Twin boring cutters unlock all kinds of flexibility in boring. One way in particular is by providing a highly productive alternative to common helical interpolation approaches. Once thought of only as light-duty, semi-finishing tools, today’s high-performance twin cutter boring heads have proven they can deliver in holemaking operations. Read more.

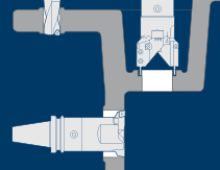

Some help finding the right BIG KAISER fine boring head

We offer one of the most complete lines of boring heads in the world. If you’re looking for the right finish boring head from our lineup, take a look at this graphic to quickly compare characteristics like connection size, balancing and insert holders.

To learn more about our vast offering of high-performance boring tool solutions for roughing, finishing and everything in between, click here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.