8 Habits of Highly Effective Boring

In an effort to capitalize on the success of Steven Covey’s bestseller, The 7 Habits of Highly Effective People, we thought we could do Mr. Covey one better with the 8 Habits of Highly Effective Boring.

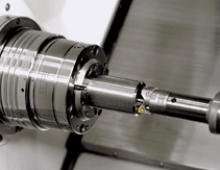

In most cases, precision boring represents one of the final touches on a workpiece that has accumulated hours of prior machining. As a consequence, the production of scrap while finish boring can result in heavy losses. Establishing the correct speeds and feeds is of the utmost importance to achieving optimum free-cutting conditions.

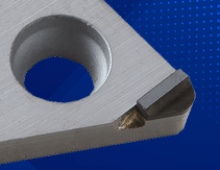

ALCRONA (AlCrN) inserts outperform AlTiN coatings to allow increased cutting speeds with no loss on insert life. They are recommended for gray & ductile iron, mild & high carbon steels, and the high temp hardness makes it suitable for tough aerospace alloys.

Without further ado, we present our eight proven habits to maximize boring success:

- Never change feed and speed in the same step; that can lead to total confusion.

- Select a preliminary speed at which you can obtain safe cutting operations without overload or vibration.

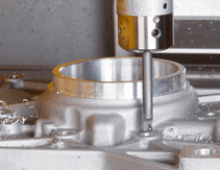

- Select a chip load in inches-per-revolution (IPR), permitting C-shaped chip form for the shortest possible chips.

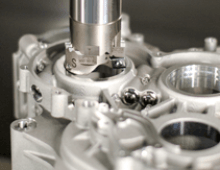

- Keep the projection ratio of your boring bar within 4:1 (L:D), or as short as possible.

- Make a trial cut and optimize the chip form by adjusting the chip load as necessary.

- Optimize the cutting speed, because high cutting speeds usually lead to better cutting conditions by maintaining the chip load.

- Use inserts designed for the lowest possible cutting forces, good chip control and unhampered chip evacuation.

- Pay careful attention to the insert wear patterns and change them before they reach the end of their useful life.

In both production runs and small-batch jobs, efforts to optimize boring operations are surely worthwhile. The principles behind optimum boring are simple, and their application is straightforward as long as you establish the right habits. Do you have a highly effective boring habit? We’d love to hear about it! Send us an email or submit a comment right here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment