Gain Peace of Mind with BIG Kaiser’s Line of Sphinx Precision Cutting Tools

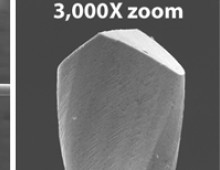

BIG Kaiser’s partner, Sphinx Tools Ltd. (Derendingen, Switzerland), is a leader in the innovation, production and distribution of precision tools for the metalworking and medical industry; manufacturing high precision solid carbide and high speed steel (H.S.S.) drills, micro drills and micro end mills. Sphinx products are supported exclusively in North America by BIG Kaiser through sales, inventory and engineering/application assistance. From micro drills thinner than a human hair to 30xD high performance drills, from coated to uncoated, from standard to special designs, Sphinx drills are the superior choice for increasing production capacity and achieving reliable results right out of the box for immediate process repeatability.

Our newest Sphinx catalog not only contains all essential physical information about these products but also includes some handy extras like recommended cutting data, application instructions, a drill geometry glossary, a drill selection chart and even a tear-out page to submit your detailed special drill request to our engineering department. See below for a few product highlights and click here to download the catalog!

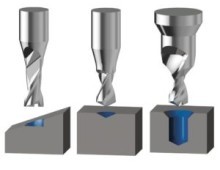

Sphinx micro drills are designed for maximum tool life, accuracy and process reliability in the smallest diameters – starting at .03mm – which is smaller than a human hair! A wide variety of unique drill point geometries, flute lengths and shank diameters are offered for use in workpiece materials including steel, stainless steel, cast iron, titanium & nickel alloys, aluminum and other ferrous materials.

Click here to learn more.

{"preview_thumbnail":"/sites/default/files/styles/video_embed_wysiwyg_preview/public/video_thumbnails/4IGUiaCwGXQ.jpg?itok=IIe3wKRm","video_url":"https://youtu.be/4IGUiaCwGXQ","settings":{"responsive":1,"width":"854","height":"480","autoplay":0},"settings_summary":["Embedded Video (Responsive)."]}

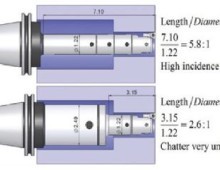

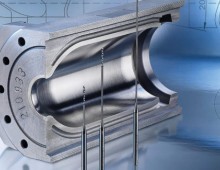

When it comes to high performance deep-hole drills, look no further than the Power-Phoenix. Designed for optimal performance in high LxD applications, the unique point grind combined with highly polished flutes allows for rapid chip evacuation, while the four margin geometry (above 2.0mm) ensures hole straightness.

Click here to learn more.

As with all BIG Kaiser products, we encourage customers to request a tool trial if they want to see our higher performance first-hand before purchasing. Our network of distributors is plenty familiar with our trial tool policy and can walk you through the process, and be there first hand through the trial.

And don’t forget, the possibilities are endless with our special tool designs. We would be happy to receive your Sphinx Special Tool Request Form and discuss your application and provide a quote for price and deliverability.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.